Maintenance

Image

BIRD™ tool for installing and maintaining beltsWith the BIRD™ (Belt Installation and Rotation Device) tool, you can safely install or check your rotary drive devices.This is because your hands and fingers are kept completely away from pinch points.

Image

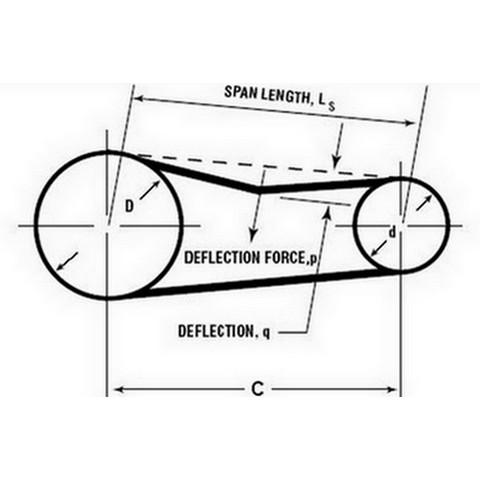

Tension of toothed conveyor beltsIf the belt is sufficiently short and free (not pressed against a sliding base), you can use the same devices as for a transmission belt. Otherwise, there is no device for measuring the installation tension.