Analysis of Synchronous belts failure

There are several possible causes of belt breakage or wear: friction, misalignment, unsuitable tension, unsuitable pulley teeth, etc.

FINDINGS

DIAGNOSTIC

TIPS

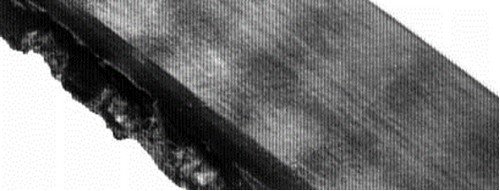

Excessive wear of the belt flanks

- Incorrect handling

- Flange damaged

- Belt too wide

- Not enough tension

- Rough flange

- Poor meshing

- Belt in contact with housing

- Follow installation instructions

- Repair the flange or replace the pulley/flange assembly

- Use an appropriate pulley

- Check tension and compare with recommended value

- Repair or replace the flange (avoid rough materials)

- Correct alignment

- Remove obstructions

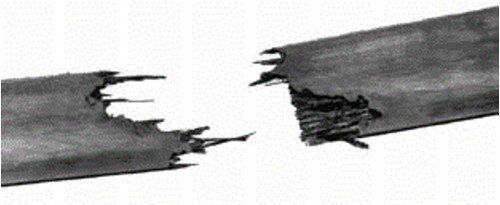

Breakage of traction ropes

- Excessive shock loads

- Insufficient pulley diameters

- Incorrect handling / storage

- Dirt or foreign object in transmission

- Eccentric toothed pulley

- Recalculate the transmission and adapt it to functional constraints

- Recalculate the transmission and use larger diameters

- Follow handling and storage recommendations

- Remove debris and check the housing

- Replace the pulley

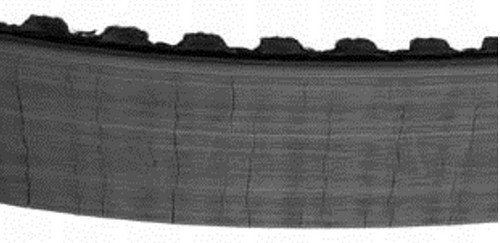

Cracks

- Insufficient pulley diameters

- Outer roller

- Extremely low starting temperatures

- Prolonged contact with harmful chemicals

- Poor hub/pulley assembly

- Recalculate the transmission and use suitable diameters

- Use an inner roller or increase the diameter of the outer roller

- Preheat the installation before starting

- Protect the transmission

- Fit the hub according to the instructions

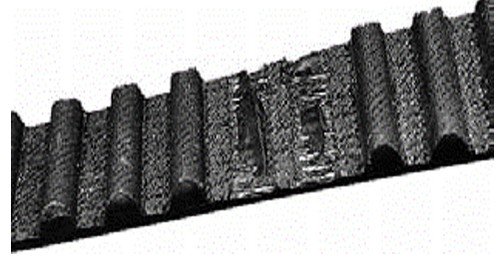

Premature wear of teeth

- Tension too low or too high

- Belt partially off pulley

- Misalignment

- Unsuitable Belt teeth (e.g. HTD®, GT, etc.)

- Worn pulleys

- Rough pulley teeth

- Damaged pulleys

- Pulleys of inadequate size

- Belt in contact with casing or supports

- Excessive load

- Pulley material not hard enough

- Dirt or foreign object in transmission

- Poor hub/pulley assembly

- Adjust to recommended value

- Correct the alignment of the non-flanged pulley

- Correct alignment

- Use correct Belt/Timing belt combination

- Replace pulleys

- Replace pulleys

- Replace pulleys

- Replace pulleys

- Remove obstructions or use a roller

- Recalculate the transmission and adapt it to the required loads

- Use pulleys of a different make

- Clean the transmission and check the housing

- Fit the hub according to the instructions

Pulling teeth

- Excessive jerking

- Less than 6 teeth in mesh

- Eccentric pulley

- Pulley wear

- Outer roller

- Unsuitable Belt teeth (e.g. HTD®, GT, etc.)

- Misalignment

- Insufficient tension

- Recalculate the transmission and adapt it to the required loads

- Recalculate the transmission

- Replace the pulley

- Replace the pulleys

- Use an internal roller

- Use correct belt/pulley combination

- Correct alignment

- Tension the Belt according to the recommended values