TA Flat belt - synthetic belt (NITTA supplier)

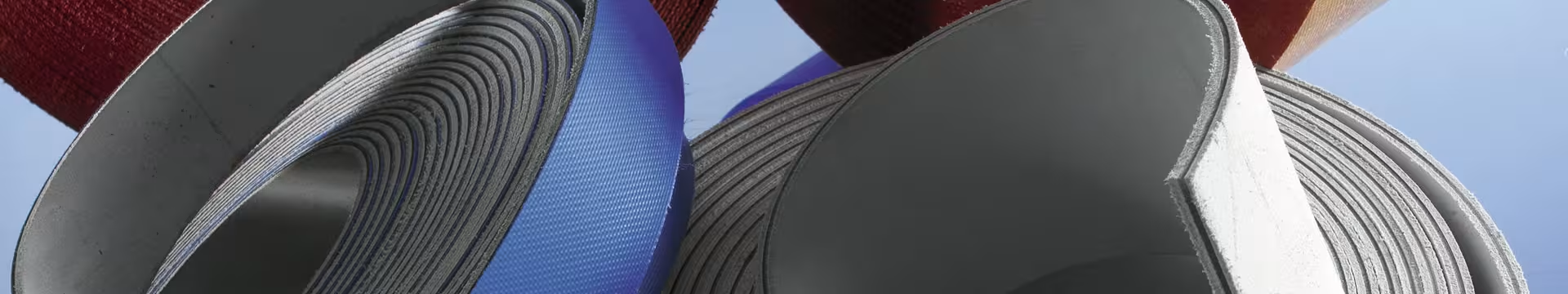

Belts made up of two friction layers of acrylic nitrile, better known under the general term "elastomer".

"elastomer".

The PA6 polyamide tensile member at the centre of the Belt is made from heated granules, extruded and then stretched to form a compact element.

The antistatic polyamide fabric placed between the tension member and the friction layers reduces the static electricity generated by the rotation of the Belt (electromotive phenomenon).

Sheet metal tensioner Belt

Teflon-coated multilayer belts

Set of Belts for Redex, Auxmet and other machines

Features :

- Teflon coating on the inside to reduce heat build-up

- High abrasion resistance polyurethane outer cover

- Can be structured for oiled coils

Application: Slitting coils

- Cutting steel or aluminium coils

- Dry or oiled coils

- Maintaining tension in coils for winding

Chromamide Belt - Bi-material leather

Belts made up of two layers of leather friction and a polyamide traction element.

Their main advantage is that they can accept slippage thanks to their leather friction layers, which are in contact with the Pulleys.

Rubber Belt with cotton interlining

Belts made from several plies of cotton canvas impregnated with rubber and vulcanised together.

The edges are coated with a red protective layer.

Their main advantage is that they can be stapled together.