Launch of the assembly tool for ERO Joint® HP and ERO Joint® B1.

It ensures belt tension and facilitates belt attachment.

Launch of ERO Joint® B1: the only quick-fit driving belt that can be made in any size.

A single pin is all you need for assembly.

Launch of the Zylon version of ERO Joint® HP. Now reinforced with Zylon Cords, ERO Joint® HP performs even better.

Launch of a reinforced cleat for very heavy loads.

Hercules is attached to the Belt's Cords, providing a genuine mechanical link between the screw-on cleat and the Cords.

Tanals is launching the NaSQaH application for its Sales Representatives and Distributors. Featuring a range of tools, the application enables Documentation and Catalogue to be synchronised and shared, and customised Belts to be quoted and ordered in 2 minutes.

Discover NaSQaH

Tanals develops its semi-automatic workshop planning system.

Since 2013, Tanals has been exporting ERO Joint® solutions in partnership with Gates, Esbelt and Behabelt.

From 2010 to 2019, 10 patents will be filed on the principles and processes used to produce ERO Joint® products. Tanals has developed these rapid assembly systems for its entire range of belts (driving belts, transport timing belts, conveyor belts, round belts, V-belts, flat belts), as well as rapid assembly tools.

Tanals completes the design and commissioning of 3 automated machines: a sleeve cutting machine, a grinding machine and a drilling/milling machine.

Tanals is also completing the development of a complete, interconnected IT system including CAPM, EDM, Sales Management, Stock Management, Costing and Planning.

In 2007 Tanals joined the sustainable development initiative and is one of the pilot companies for the Alsace Excellence programme (implemented by the CCI).

At the end of 2004, the company's focus shifted towards increasingly technical expertise, with the arrival of Pierre-Régis Frey, an INSA engineer, who was appointed Chairman on 1 July 2007.

Installation of a CAPM (Computer-Aided Production Management) and Document Management system.

Following the appointment of Thierry Frey as CEO in 1990, the company's production facilities were expanded, notably with the purchase of a cutting machine for endless flat belts and timing belts, followed in 1998 by the design of a numerically-controlled bevelling machine.

In 1985, the first computerisation of the accounting and sales management departments.

In 1973, Charles Frey, the founder, retired, and was succeeded by his son Jean, while his grandson Thierry joined the company. At that time, the company had 27 employees.

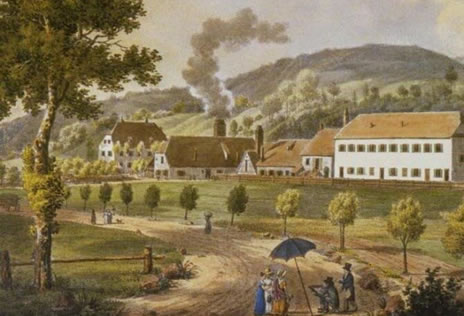

In 1936, Mr Charles FREY bought the tanning factory in Masevaux to start manufacturing industrial leather belts.