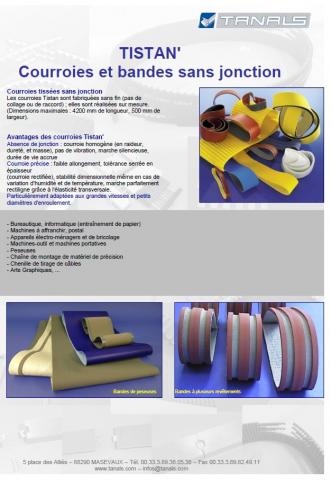

Polyurethane (PU) endless woven belts

PU is a compact sprayed and rectified foam with a hardness of 50 shores A (other hardnesses on request), and a maximum thickness of 10 mm.

PU has very good abrasion resistance and a good coefficient of friction, and can withstand temperatures of up to 70°C.

Yellow or grey (other colours available), its role is to coat the woven fabric, ensuring good adhesion to the Pulleys.

Neoprene endless woven Belts (NE)

With a hardness of 75 shores, neoprene has very good abrasion resistance, a high coefficient of friction and very good temperature resistance (130°C).

Neoprene is generally calendered on both sides of the belt and ground to a constant thickness (maximum thickness 1.8 mm).

Advantages of TISTAN Belts :

- Customised dimensions

- Small winding diameter

- Good abrasion resistance

- Good resistance to oils

- Temperature resistance (NE)

- Constant thickness (obtained by grinding)

Common applications : Office automation, Portable electrical equipment, Saws, Textile machines, Graphic arts, Postal services, Machine tools, Turbines, Printing tracks, etc.