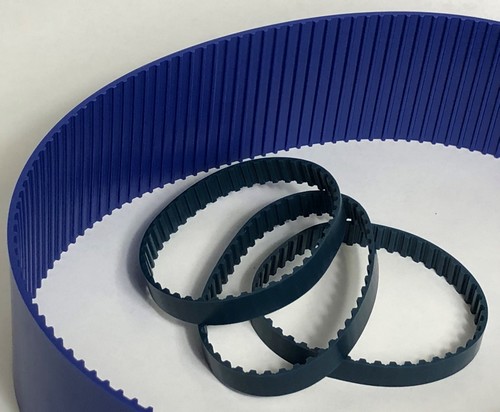

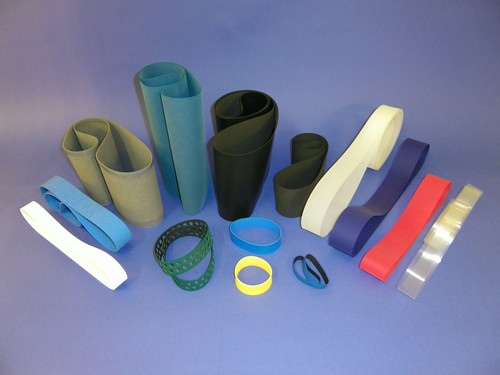

Range of Polyurethane elastic belts

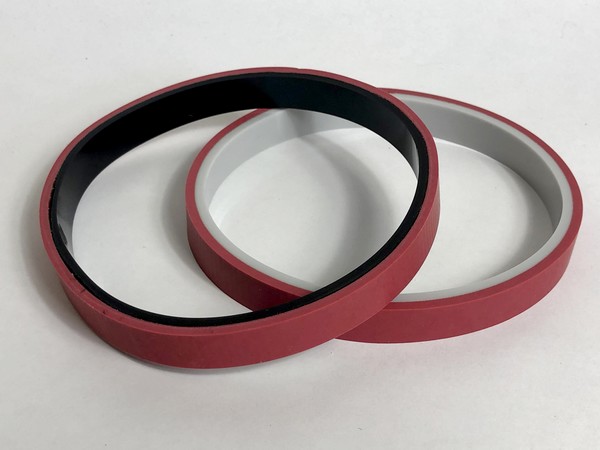

We can produce multi-layer belts (with several polyurethanes of different hardnesses from 35 shore A to 55 shore D) and also incorporate other coatings (Sylomer, Linatex, etc.).

We can work with all the coatings used in the belt and conveyor belt industry (polyurethane, PVC, rubber) with or without structure on any type of support (flat, toothed, ribbed, V-belt or conveyor belt).

All the coverings in our range can be joined by gluing or fusing for polyurethanes and PVC. Some coverings, such as Linatex® and polyurethane foams, can be made endless.

Sylomer coating

Linatex coating

PU foam coating

Supergrip PVC coating

Materials

We have developed our own belts for specific applications. To do this, we have developed a method for characterising materials and testing relaxation. We have tested the materials in our range, those of our partners and our colleagues, as well as other polyurethanes, in order to select the most interesting materials according to technical criteria (adhesion, abrasion resistance, etc.), service life (resistance to relaxation over time), stability (temperature, humidity) and price.

Thanks to our experience in the field of elastic belts (working in partnership with several major manufacturers for over 20 years) and our in-depth knowledge of the relaxation and ageing of our materials, we can offer you the solution best suited to your application, while ensuring optimum value for money.

Since 2012, we have been developing our own polyurethane with particularly high relaxation and abrasion performance, to make endless elastic belts and belt coatings.

The elastic belts are made from polyurethane and can comply with the FDA and/or European regulations EC1935/2004 and EU/2011.

They can also be detectable by metal detectors, resistant to hydrolysis, UV-resistant, antistatic, and limit the growth of micro-organisms, depending on the version.

Splices

In order to obtain the most homogeneous belts possible for the most demanding applications, we have developed several splicing processes. (minimum length 80mm, invisibility of the splice, perfect homogeneity of the Belt, preservation of the structure of the base material, etc.).

We can also produce endless belts without splices under 2m in length. These belts can be structured, perforated, multi-layered, fitted with foam, etc.

Grinding

The need for perfect control of belt stiffness (to limit stress on the axles while ensuring the belt's function throughout its life after relaxation) has led us to develop two grinding machines that enable us to achieve +/-0.05mm thickness tolerance and particularly precise and stable coefficients of friction.

Each elastic product is specific, so we choose the most suitable material for the application and shape it (spliced or endless) to the required dimensions (the length at rest is calculated taking into account the permissible axial forces and the ability of the chosen base material to resist relaxation).

POSSIBILITIES

Length: from 80 mm to 6000 mm

Width: from 3 mm to 1000 mm

Thickness: from 0.6 mm to 6 mm

Hardness: 35 Shore A to 55 Shore D

Colours: black, blue, red, grey, yellow, white, transparent,

others on request...

Food suitability: FDA and/or EU 10/2011

Antistatic version

Temperature: stable PUs from -20°C to over 100°C