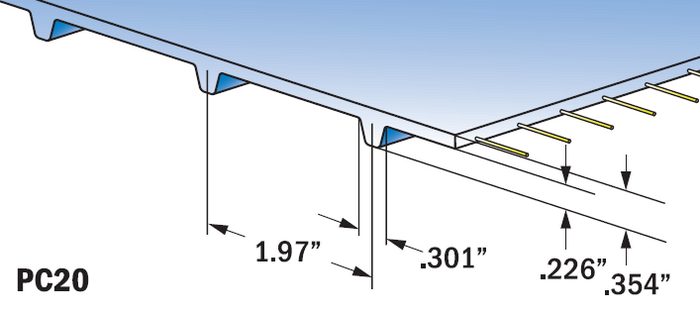

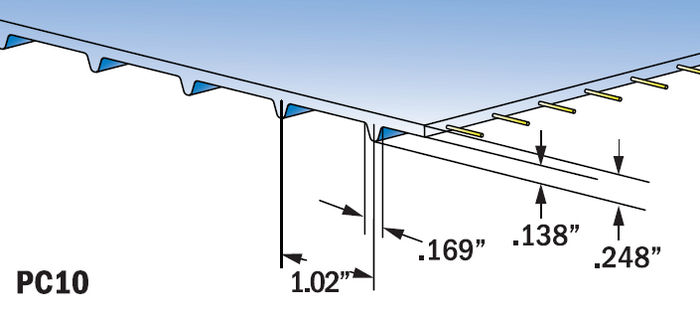

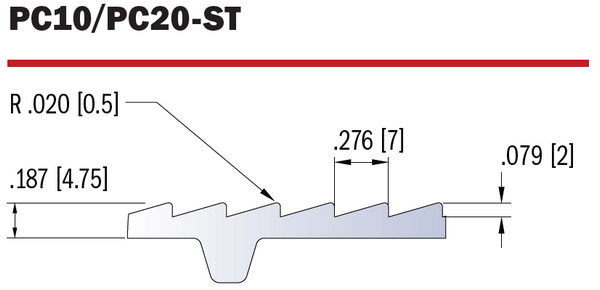

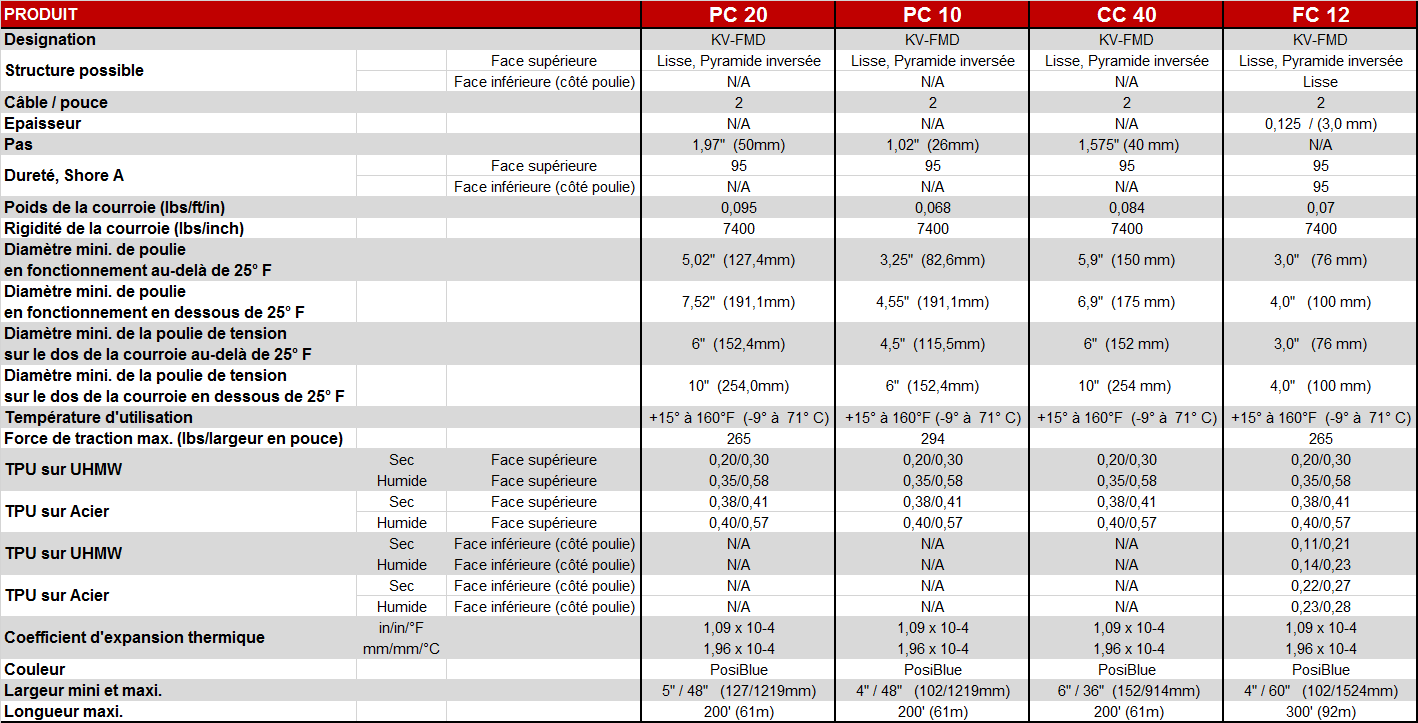

POSICLEAN® PC20 and PC10 jointed food tape

The POSICLEAN® PC20 and PC10 food belts manufactured by GATES and processed in our workshops are synchronous polyurethane belts. It has been designed to replace modular belts and other plastic chains to facilitate the cleaning of food preparation lines.

It has embedded aramid traction Cords to limit belt elongation, and perfectly smooth surfaces for easy cleaning. It is totally hermetic, which reduces microbial growth.

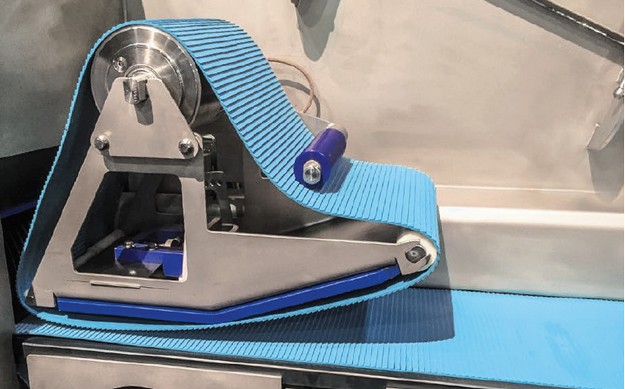

Positive training

Easy-to-clean belts

Two pitches available: 50 mm and 25.9 mm

Full-width drive teeth for even torque distribution and embedded aramid Cords (high load capability)

Widths up to 48

Compared to a modular belt :

- Easier to clean

- No hinges or pins to break and potentially contaminate the product

- Quieter operation

- 30% less weight.

- Available in a reinforced version for heavy loads

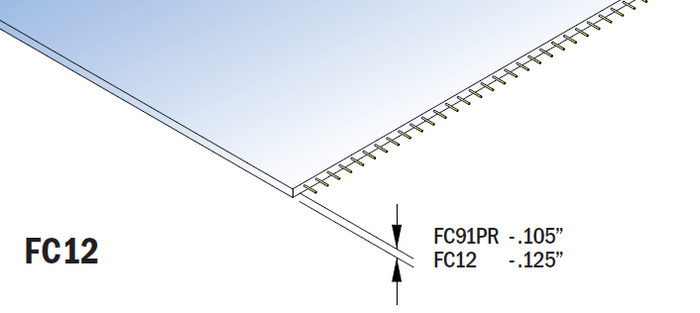

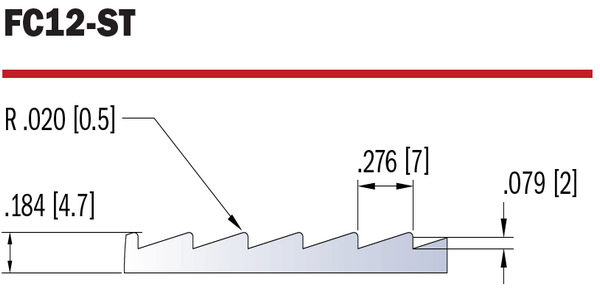

FLATCLEAN FC12™ Spliced Food Belt

FLATCLEAN FC12™ food grade belt manufactured by GATES and processed in our workshops, is a flat polyurethane belt reinforced with aramid tensile cords. This belt is designed specifically for food applications.

It has smooth surfaces and sides that are easy to clean. It has high strength and low elongation. It is also extremely resistant to cuts and abrasion resistance. Totally hermetic, it limits microbial growth.

Flat belt in polyurethane

With aramid traction Cords

Width up to 60

Compared to textile pleated tape :

- Does not fray

- More dimensionally stable

- Longer service life

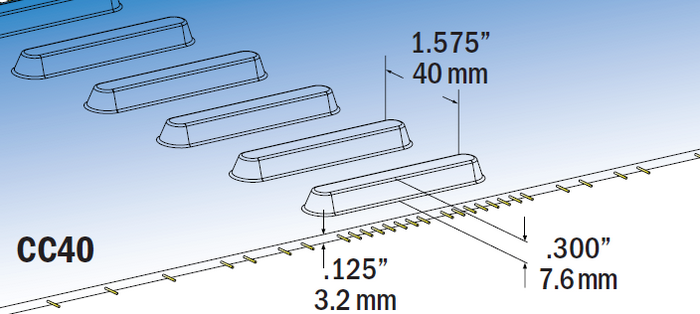

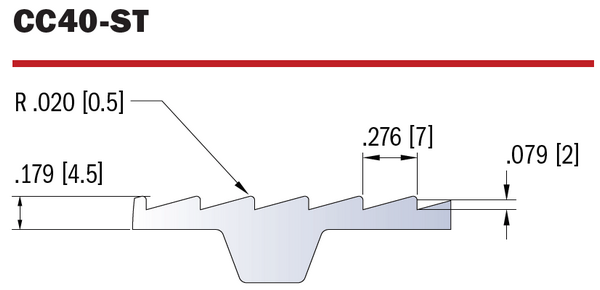

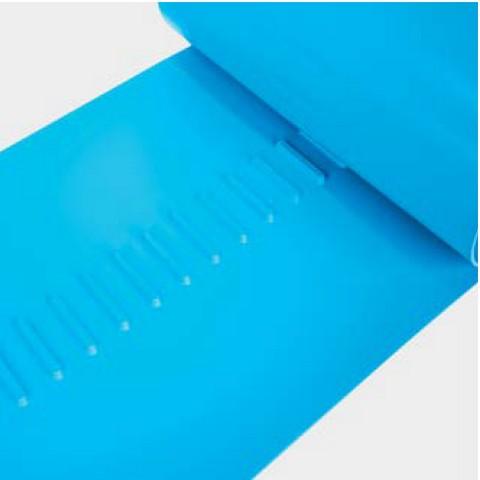

CENTERCLEAN™ Spliced Food Belt

CENTERCLEAN™ CC40 food belt manufactured by GATES and processed in our workshops, is a polyurethane belt, designed with sealed aramid tensile cords to limit belt stretch and smooth surfaces to facilitate microbiological cleaning.

Drive teeth in the centre over a width of 3

40mm pitch

With aramid traction Cords

Widths up to 48

Suitable for trough applications

Compared to textile pleated tape :

- Does not fray

- More dimensionally stable

- Longer service life

There are various structured belts for transporting foodstuffs in compliance with food standards

CE 10/2011 and FDA/USDA.

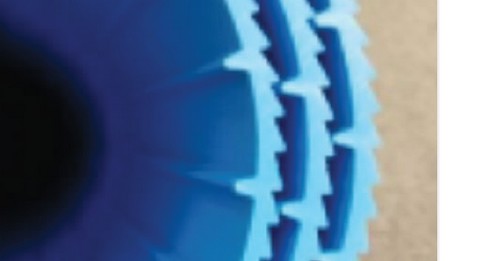

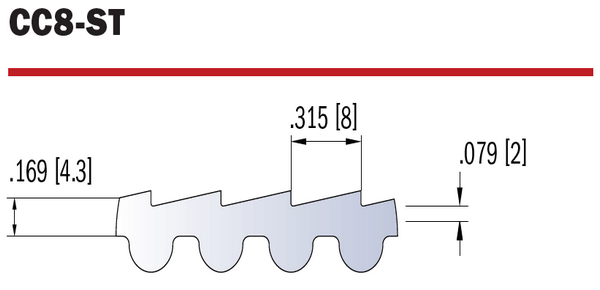

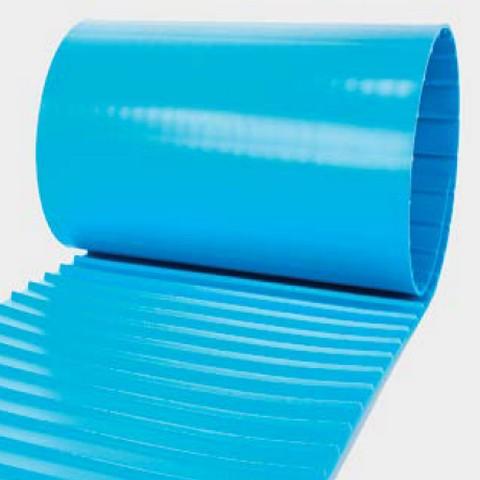

SAWING TEETH (ST) 90° Sh A

Ideal surface for meat, slicers, high friction applications to minimise product slippage when cutting

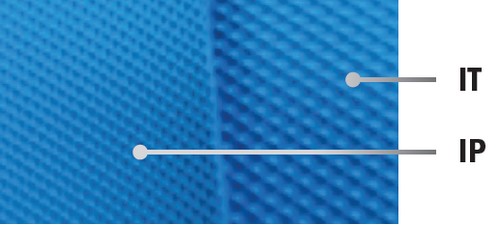

Inverted Tetrader (IT) and Inverted Pyramid (IP) 95 ° Sh A

Surfaces suitable for applications requiring rapid product transfer

(limitation of the suction cup effect which prevents the release of the transported product)

Advantages of this product range:

- Fully sealed edges → no risk of bacterial contamination

- Integral Cords provide high load capacity and eliminate the risk of elongation → (No re-tensioning required)

- Robust polyurethane, ideal for high abrasion environments

TECHNICAL DATA :

Operating temperature: -10 to 70°C

Hardness: 90 Shore A (ST)

95 Shore A (IT/IP)

Colour: blue or white

Standard roll length: 61m

Joints: standard sawtooth, butt, Posilace or ERO Joint®.