Tools for splicing Polyurethane and/or Polyester round and trapezoidal belts

We offer a wide range of tools and accessories for splicing your BEHAbelt round and V-belts.

Range of welding machines :

EErgo

Multi TC

SG02

SG03

Welding method with EERGO tool (PU and TPE), Multi TC, SG02 (PU) or SG03 (TPE)

Heat the purlin to the desired temperature

Attach the clamp to the 2 ends of the Belt and align them.

Place the welding rod between the ends of the Belt. Press on the guide clip and the ends of the Belt

If a 2-3mm bead appears at the ends of the Belt, quickly open the pliers and remove the defect.

Place the clamp on its base and allow the Belt to cool for 10 minutes.

RS02 friction welding machine

Choosing and using clamping jaws

Fix the profile to the centre of the clamping jaws and secure the clamping jaws with an Allen key.

The parameters for regulating the melting speed and the pressure contact depend on the type of profile

Switch on the machine and press the release button

Stop as soon as the profile swells, the profile is welded. Leave the welded profile in the machine for approx. 2 to 3 minutes and then open the clamping jaws with the Allen key.

Welding using an HP01 press

Inserting the profile into the mould

Close the top of the mould and position it in the press

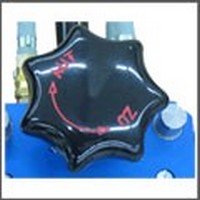

Turn the knob to close the press

Press the Start button

When finished, open the press and remove the profile from the mould.

Fusion using FZ03 tooling

Select the clamping parts and insert them into the FZ03

Attach the ends of the prepared Z-shaped belts by overlapping them in FZ03.

Merge profile

Quickly remove the welding tool and close the FZ03.

Allow the profile to cool in the appliance. Remove any burrs using the SE02 cutter.