Conveyor belt adjustment

When a belt is off-centre to the right or left, it is a problem of alignment or tension.

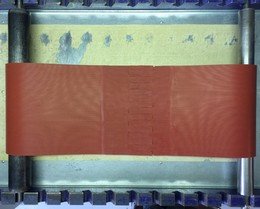

A.

- The belt must be sufficiently taut (it must not slip on the rollers).

Excessive tension can damage the splice and/or conveyor components. - The belt should be tensioned gradually, alternating left and right tension to keep the rollers parallel.

- Clean the belt and ensure that no objects interfere with the adjustment.

The joint should be as straight as possible. It can be made at an angle, but the cut must be precise.

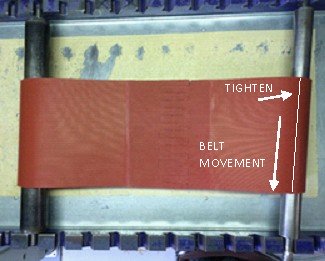

B.

- Check that the rollers are parallel to each other. Each roller can independently interfere with correct adjustment.

- Ensure that the rollers are perpendicular to the belt and conveyor structure.

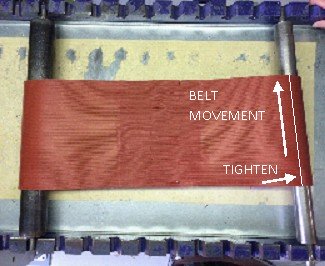

C.

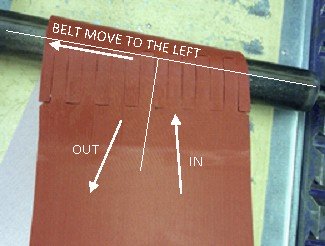

- After starting, if you tension to the left, the belt should go to the right and vice versa (see images B and C).

- If the setting is correct, check with the load. A loaded belt may react differently.

- If the belt is too taut, reduce the force alternately to the right and to the left (reverse of step 2).

Recommendations and warnings

A few tips on aligning the belt

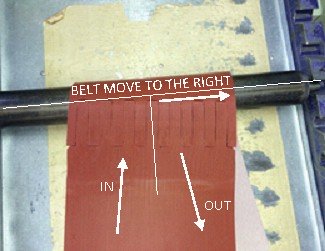

D.

1. A thin strip will always be easier to adjust than a thick, rigid strip. A thin tape wraps more easily around the rollers.

2. Wear on the drive roller cover can cause belt instability.

3. If you notice that the belt reacts in the opposite way to what we saw earlier, i.e. if when tensioned to the left, the belt moves to the left, this means that it is not guided by the tension but by the orientation of the rollers. See images D and E.

E.

4. If the belt is wide in relation to its length and rather thick in relation to the diameter of the rollers, it can be difficult to adjust. Use as thin a belt as possible to make adjustment easier.

5. A loose belt cannot be adjusted properly. The belt should be tensioned and adjusted before a load is placed on it to avoid slippage on the rollers.

6. A heavy load that is incorrectly positioned -> off-centre or a side load will systematically push the belt to one side. In this case, use a drive guide under the belt.

In all cases, take care to tension the strip gently and symmetrically, and not to pull too hard so as not to damage the joint.