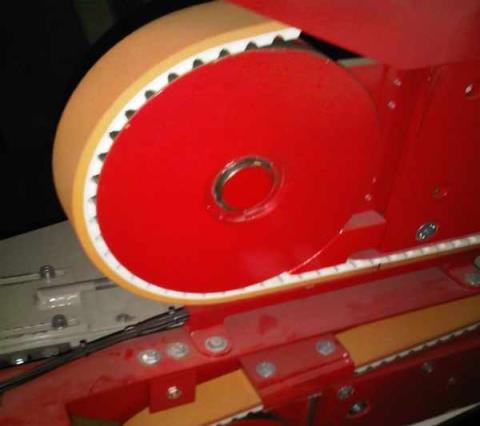

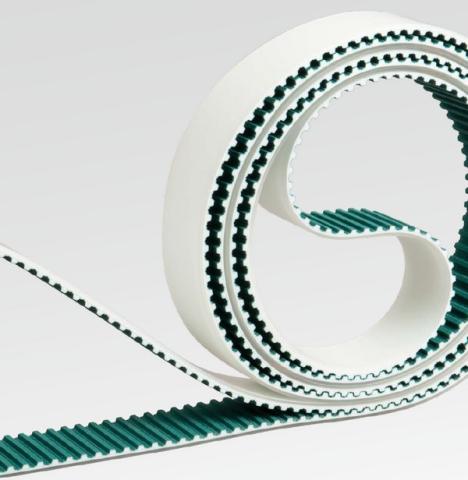

Since the beginning of 2008 Tanals has been the official "Fabricator" for the entire Gates linear Timing belt range.

The only Gates Fabricator in France.

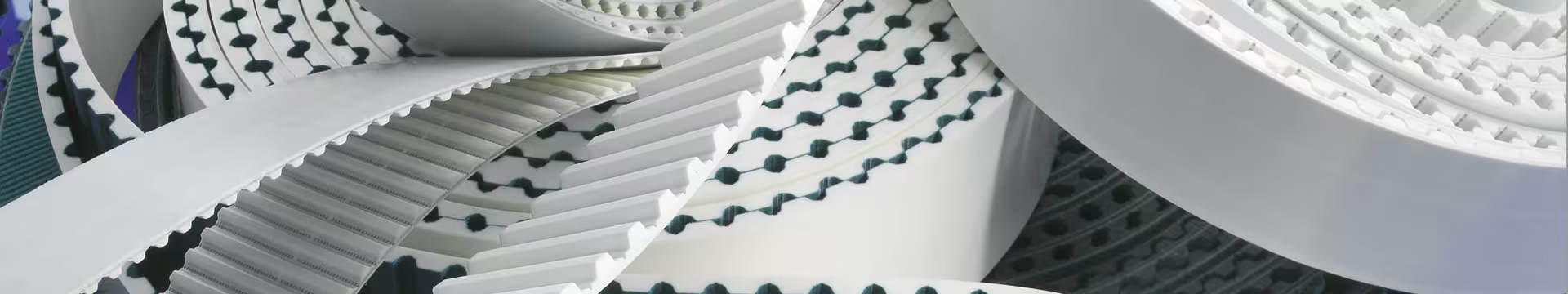

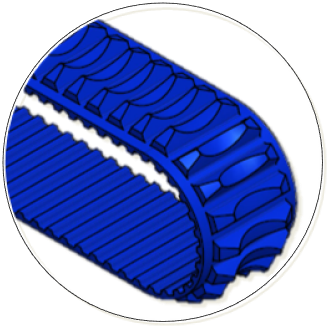

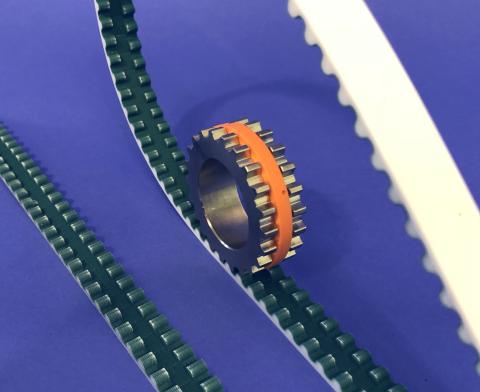

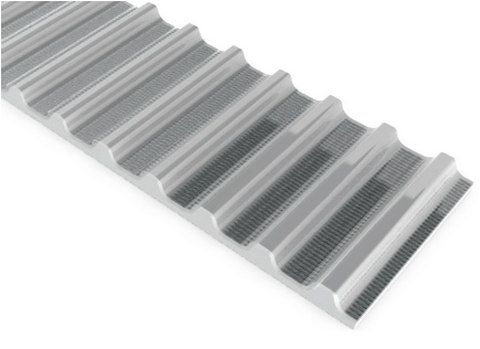

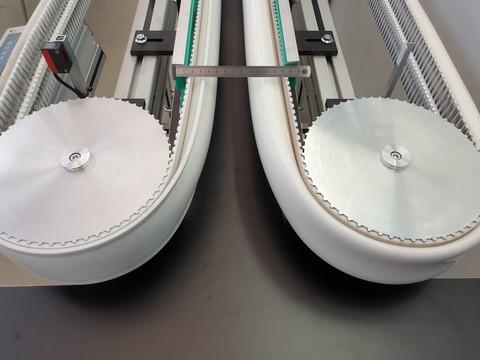

We have access to Gates calculation software and our own resources for dimensioning your installations. Our processing and storage facilities enable us to quickly cut and splice your linear Timing belts. We can fit the most common coverings, drive guides and cleats, as well as perforating and machining in our workshops.

Our belts can be cut to length, welded, seamless or mechanically spliced.

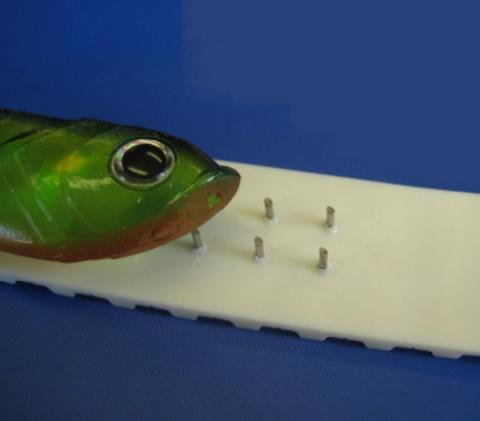

ERO Joint® HP polyurethane belts

Replace your polyurethanebelts quickly with our patented ERO Joint® HP (Hinge Pin) mechanical joint system!