Hauteur

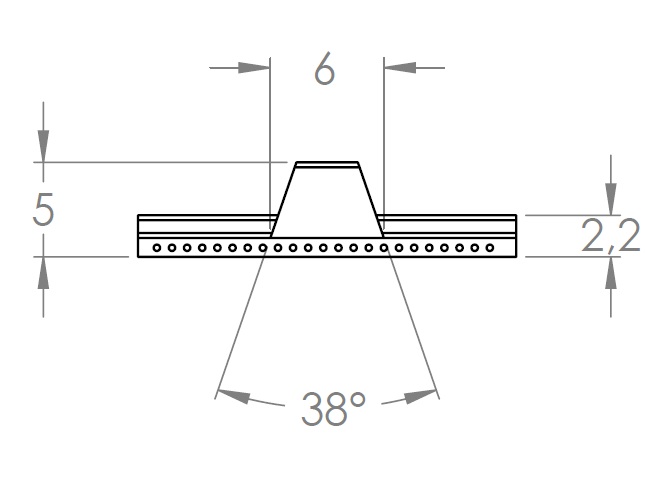

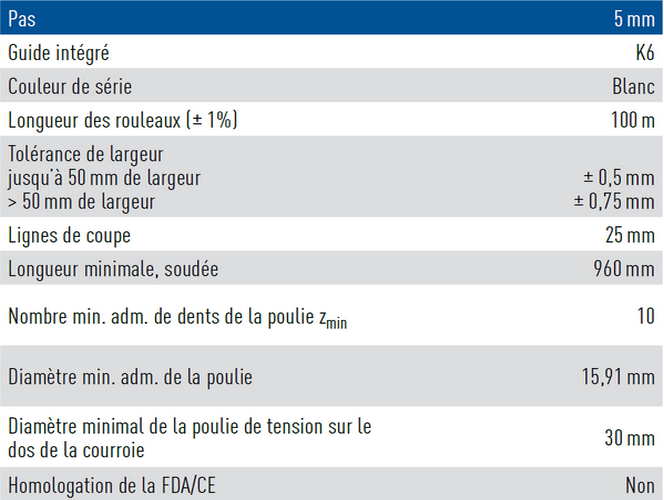

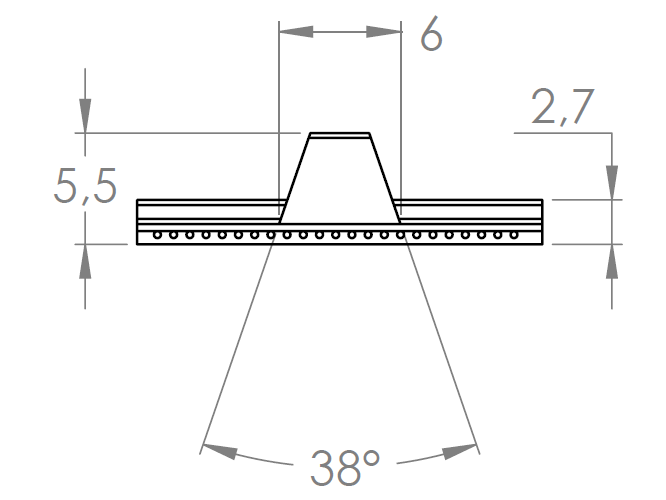

Belt with integrated T5V drive guide

Hauteur

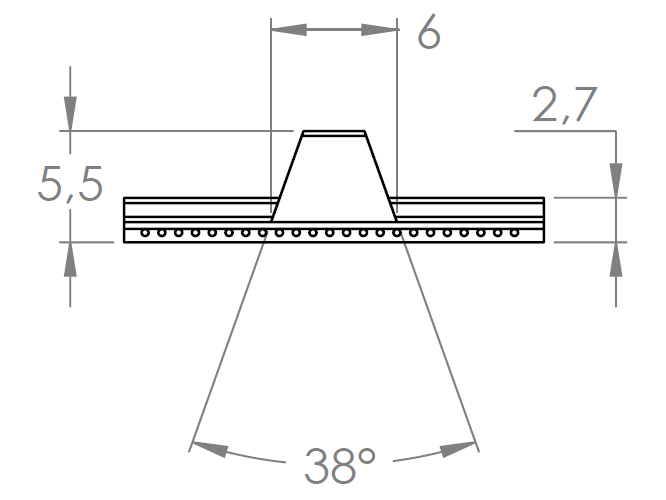

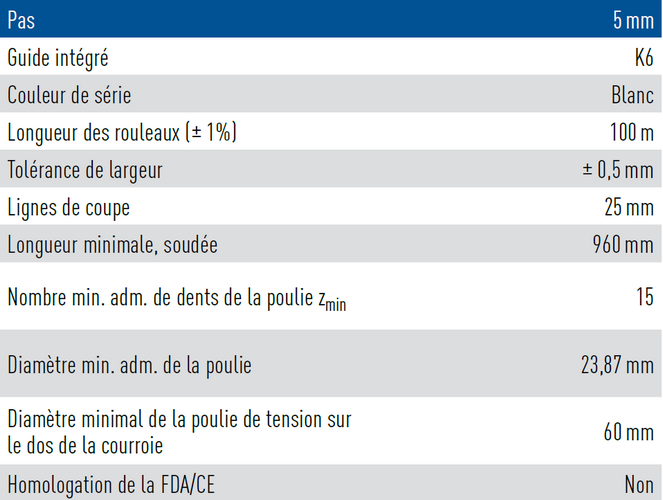

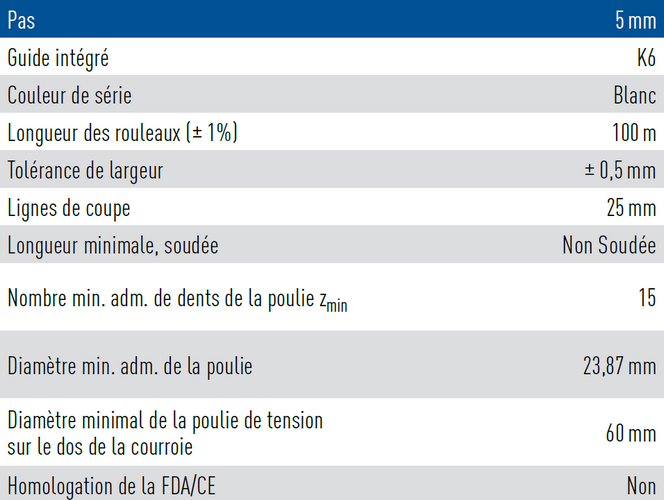

Belt with integrated drive guide AT5V

Hauteur

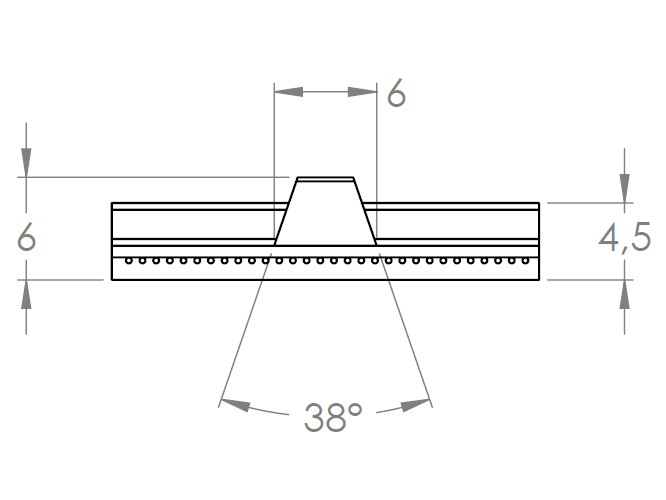

Belt with integrated drive guide ATL5V

Hauteur

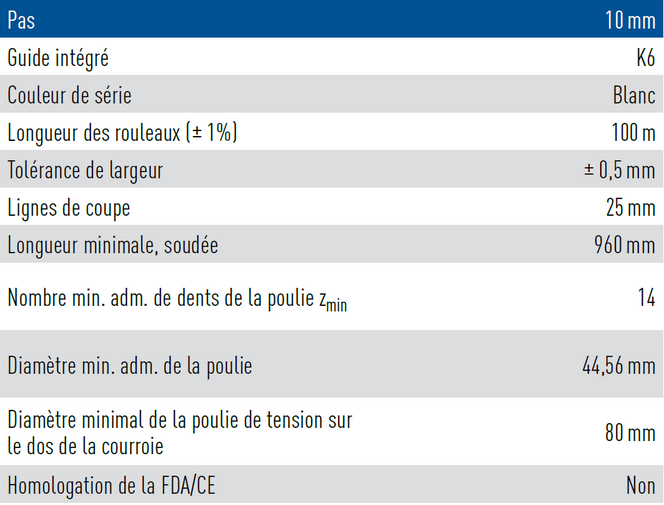

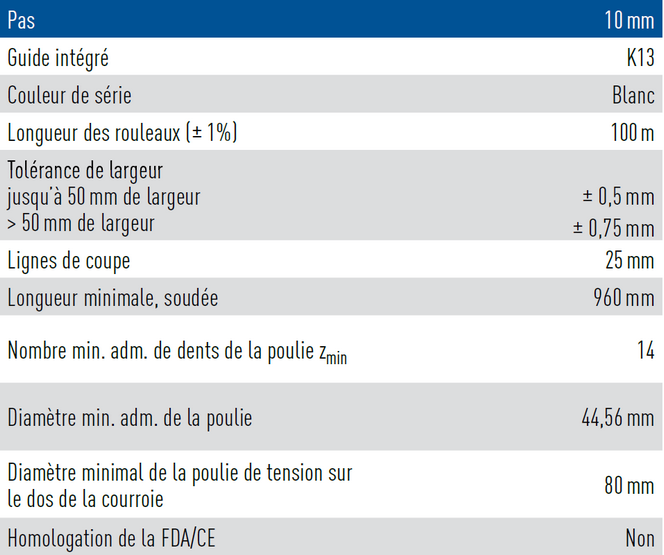

Belt with integrated drive guide T10VS

Hauteur

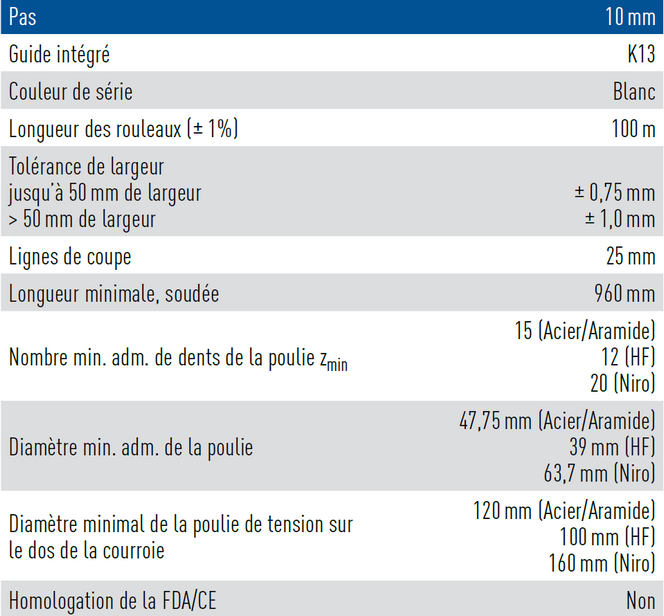

Belt with integrated T10V drive guide

Hauteur

Belt with integrated drive guide AT10V

Hauteur

Belt with integrated HV drive guide

Hauteur

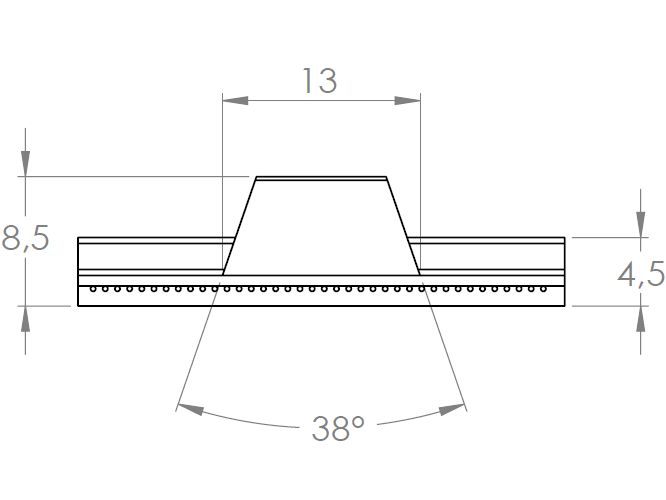

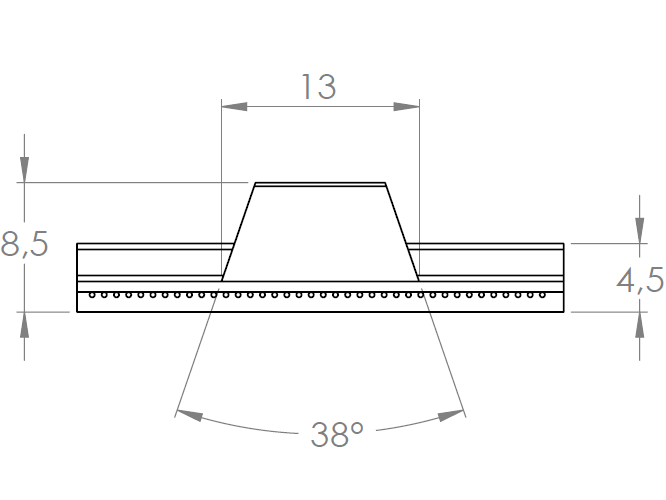

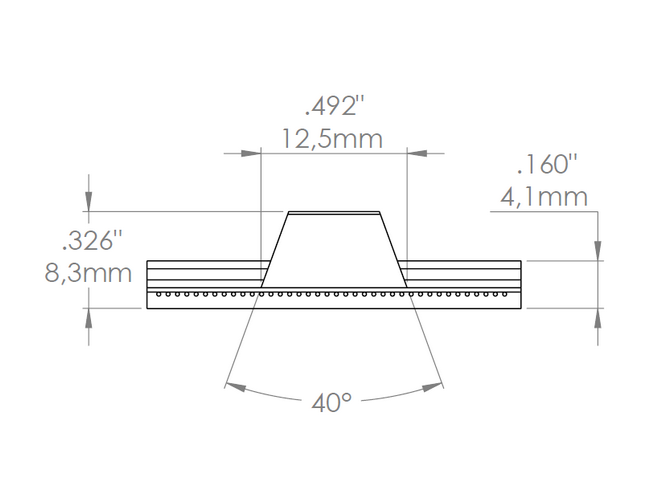

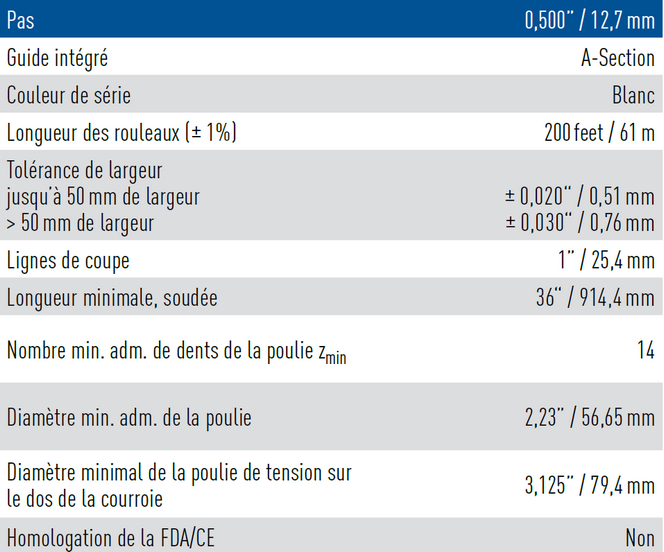

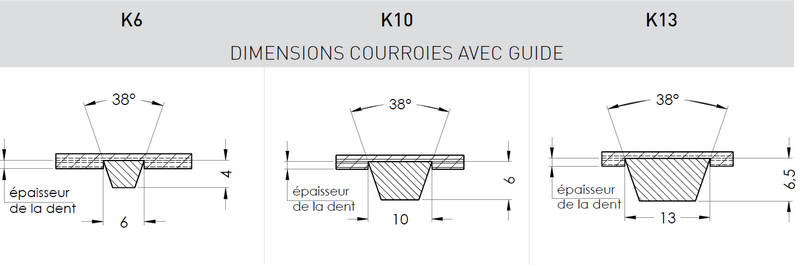

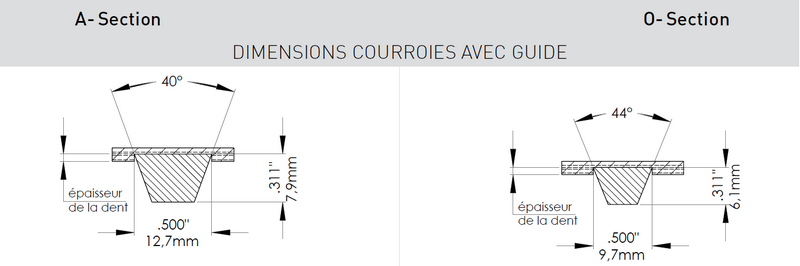

Dimensions of the guide profile inserts :

The Belt is machined to create a groove and the trapezoidal guide profile is fused into this groove.

There are guide profiles specifically adapted to timing belts, but polyurethane conveyor belt profiles can also be used (preferably notched to reduce winding diameters).