Polyurethane belts with mechanical assembly - ERO JOINT® HP

PITCHES: T5 - AT 5 - H - T10 - AT10 - T20 - AT20 - 8M - 14M - WT10 - WH

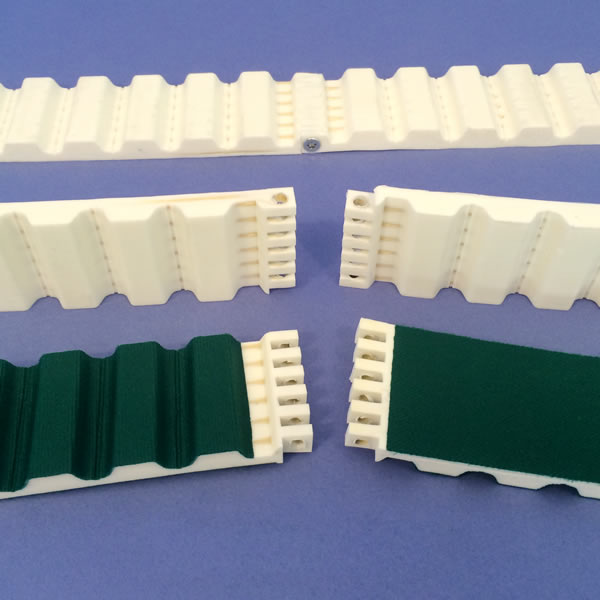

The ERO Joint® HP "Hinge Pin" mechanical joint system (patented) can be used for any width from 10mm to 450mm with any type of Reinforcement, drive guide and coating.

The mechanical strength of ERO Joint® HP is equivalent to that of a welded joint.

They allow you to replace your Belts very quickly.

European aid of €15,225 has been granted to finance the expansion of the ERO Joint® HP range, process optimisation and increased production capacity.

To find out more, click here:

Quick-assembly driving belt - ERO Joint® B1

Available in 8M and 14M lengths

ERO Joint® B1 is a driving belt designed for rapid assembly, particularly suited to maintenance operations. It can be used to replace any standard driving belt during a machine stoppage, without the need for complex dismantling.

Its assembly method is similar to that of a chain: independent modules can be linked together to form a belt of any length, with no dimensional constraints. Assembly is carried out manually, by screwing in the pin, without any special tools.

Since 2017, we have been developing the "Belt Chain" concept, a hybrid solution combining the advantages of belts (clean running, silence and dimensional stability) and those of chains (open assembly and the possibility of adjusting length by adding sections).

Ten years after the launch of ERO Joint® HP - a fast-assembly conveyor timing belt renowned for its performance - we are now extending this technology to power transmission.

To simplify installation and adjustment, a Belt tensioning tool is available as an option, making it easy to install on the machine.

To find out more, click here:

Poly Chain® Carbon™ Volt® ERO JOINT® Ultimate

PITCH: 8MGT - 14MGT

The patented principle of the ERO Ultimate splice enables the on-site assembly of a Belt with half its width continuous. This results in extremely high mechanical strength and service life.

Poly Chain® GT Carbon™ ERO Joint® Ultimate transmits more power than any rubber driving belt and can replace any standard belt. A Polyurethane T10 ERO Joint® Ultimate belt withstands more than 50% of the load of a Flex (continuous Cords) belt.

This type of joint can be made in any Timing belt with a pitch greater than or equal to 8mm.

To find out more, click here:

Poly Chain® Carbon™ Volt® ERO JOINT®

PAS: 8MGT - 14MGT (can also be fitted to 8M and 14M HTD for repairs)

Poly Chain® Carbon™ Volt® ERO Joint® and ERO Joint® Ultimate are quick and easy mechanically assembled belt solutions.

Used for troubleshooting or long term, they allow you to replace your Belts very quickly.

Find out more:

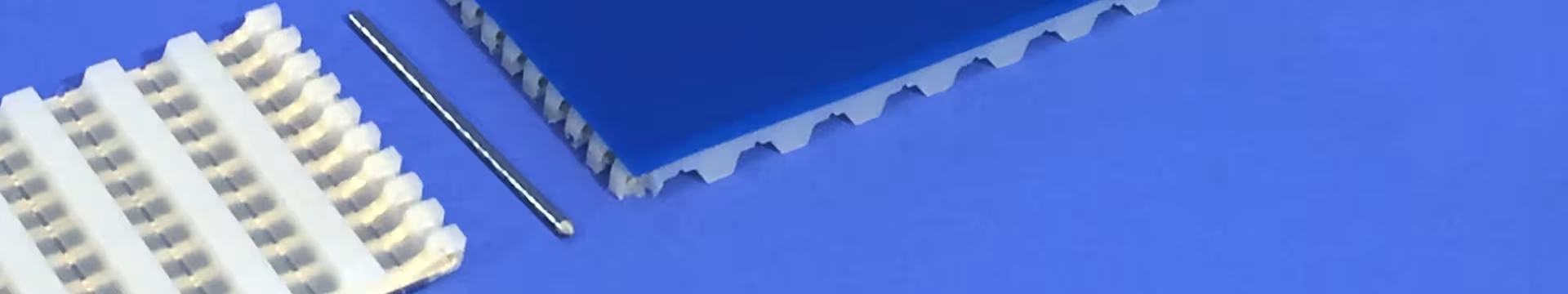

Polyurethane belts with mechanical assembly - ERO JOINT® WT

PAS: WT10 - WH

ERO Joint® WT (Wide Timing) joints (patented process) for large widths can be used for all pitches and for any width greater than 100mm.

To find out more, click here:

Conveyor Belts with Mechanical Assembly - ERO JOINT® Conveyor Belts

ERO joints (ERO Joint®) can be used in virtually all types of Conveyor Belt.

This fast, practical mechanical assembly solution allows you to replace your Conveyor Belts on site without dismantling them.

To find out more, click here:

Mechanically assembled polyurethane belts - ERO JOINT® (pin joint)

PITCHES: 8M - 14M - T10 - AT10 - T20 - AT20

ERO Pin Joint (ERO Joint®) can be made for any width from 16mm to 100mm, for low-load applications.

They allow you to replace your belts very quickly.

To find out more, click here:

Polyurethane and polyester belts with mechanical fasteners - ERO JOINT®

Round belts are available in diameters from 8mm upwards. V-belts are available from profile 17x11.

Different types of mechanical assembly are possible.

The mechanical elements are connected to the tensile core to ensure maximum mechanical strength.

To find out more, click here:

ERO Joint® Polyurethane and Polyester belts with mechanical connection

Flat belts with mechanical fasteners - ERO JOINT®

There are several possibilities for mechanical assembly using Flat belts. These solutions are primarily troubleshooting solutions.

The service life of mechanical assemblies for high-speed and/or small-diameter installations is limited.

To find out more, click here:

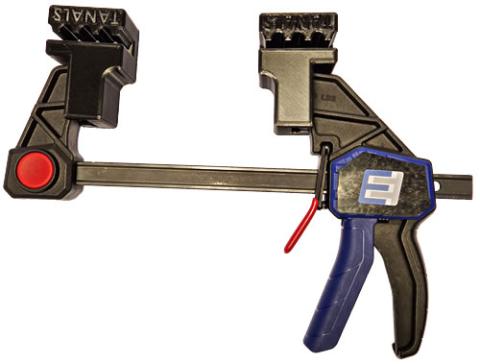

Assembly tools for ERO JOINT® Timing belts

Although no tools are required to assemble ERO Joint® Timing belts, the tensioning and assembly tools make assembly quick and easy.

Find out more here: