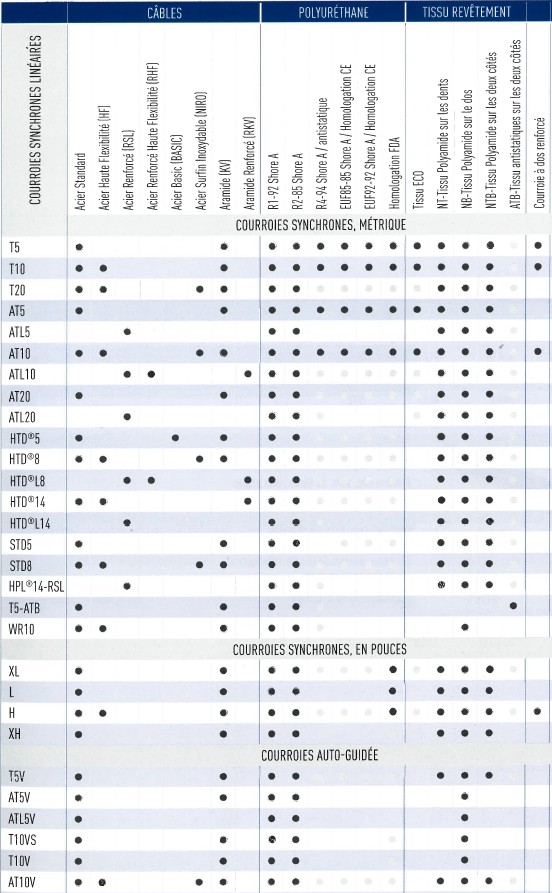

Pitch in inches

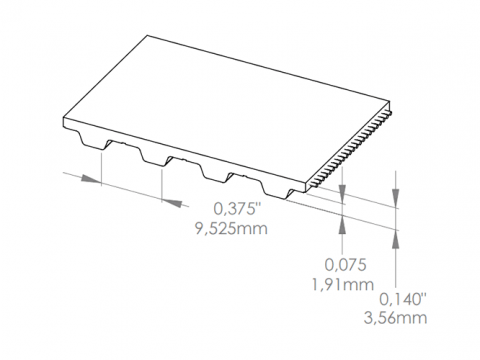

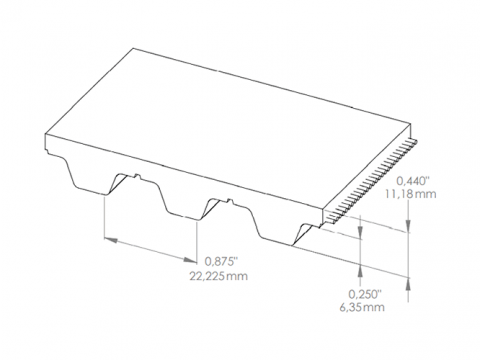

PITCH : XL- L- H- XH

The classic trapezoidal profile is the original tooth design of timing belts. This profile can be used in transport and power transmission applications. The width of the teeth ensures good load carrying capacity on the sliding surface. This profile is suitable for less demanding applications.

L - 9.525 mm pitch

XL - 5.08 mm pitch

H - 12.7 mm pitch

XH - 22.225 mm pitch

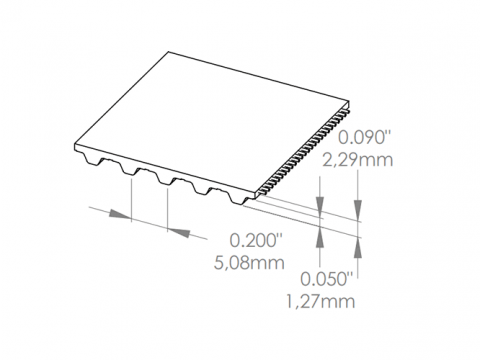

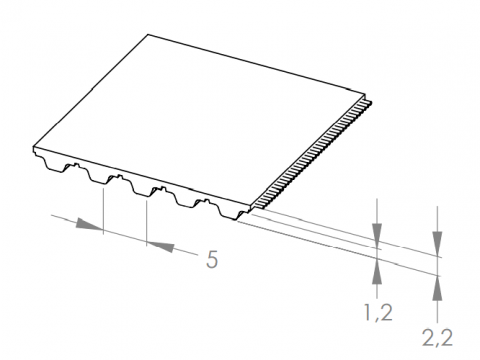

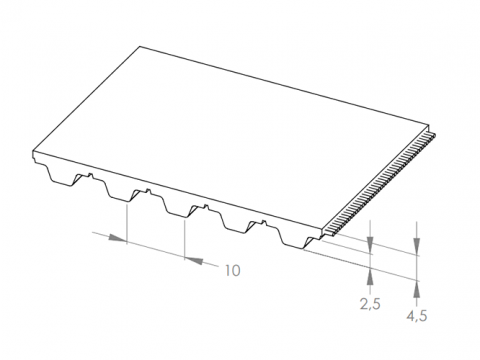

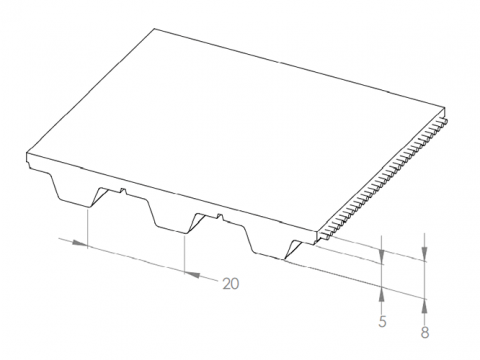

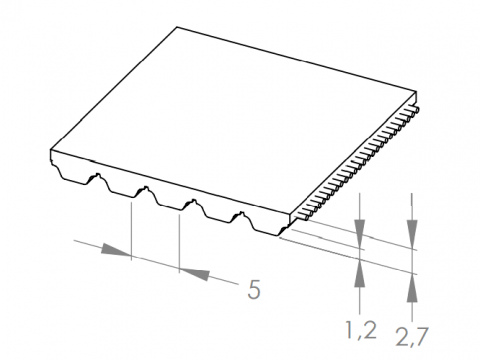

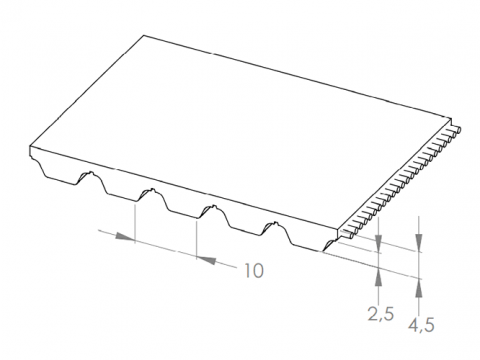

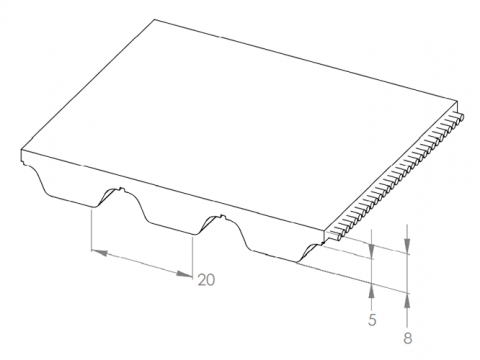

T profile

PITCH: T5- T10- T20

This trapezoidal profile, here in metric pitch, is the original design of timing belts.

It is usually used for transport and power transmission applications. Compared with the inch pitch profile, the tooth is higher, which reduces the risk of tooth skipping, but the backlash is slightly greater.

This profile is suitable for less demanding applications.

T5 - 5mm

T10 - 10mm

T20 - 20mm

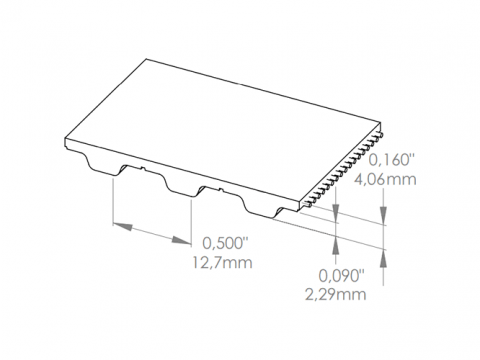

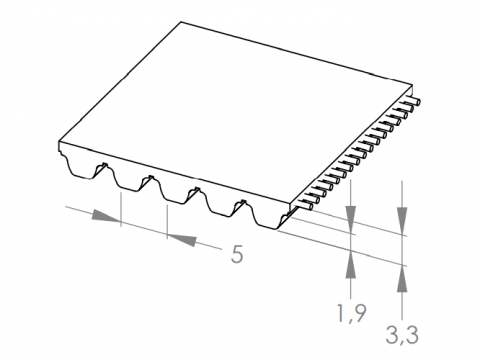

AT profile

PITCH: AT5- AT10- AT20

This profile has been developed to provide greater load capacity and reduced backlash. The stiffer teeth make these belts ideal for linear positioning and motion control, but may require larger diameter pulleys.

AT5

AT10

AT20

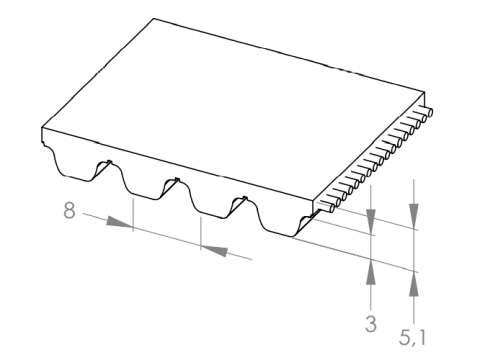

STD Profile

PITCH:STD5- STD8

This profile ensures better load distribution on the tooth, reduced backlash, less wear and less noise.

It is a good profile for linear and rotary positioning as well as high-speed power transmission.

STD5

STD8

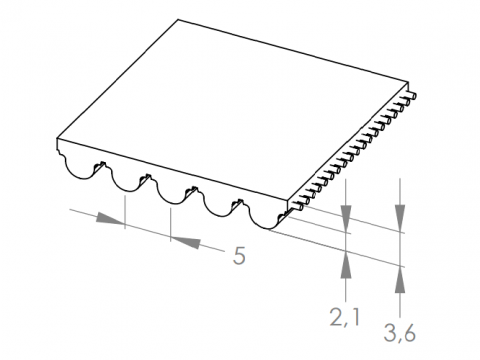

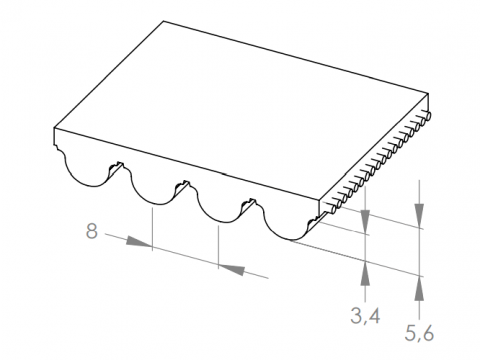

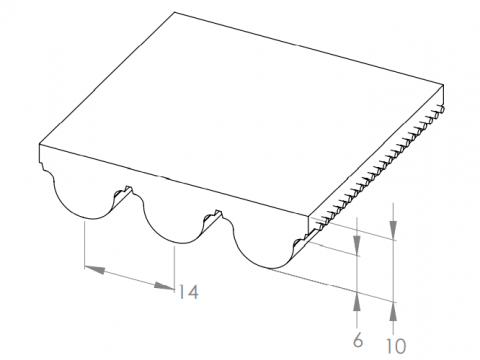

HTD Profile

PITCH: HTD5- HTD8- HTD14

This rounded profile was originally developed for power transmission. It is excellent for linear and rotary positioning as well as power transmission.

The higher teeth reduce the risk of teeth jumping compared with trapezoidal profiles, but this profile is noisier and more sensitive to wear.

HTD5

HTD8

HTD14