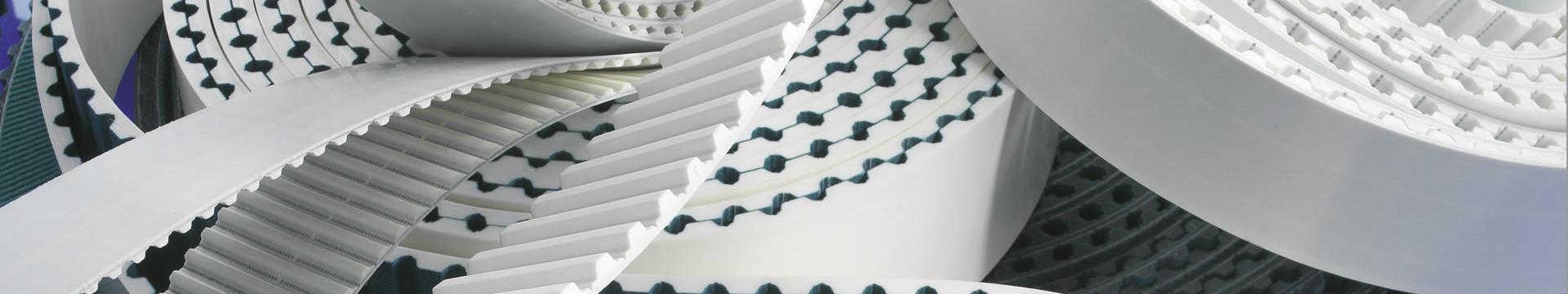

For Flex belts, steel or Kevlar® cord is used in closed loops to ensure maximum tensile strength.

Flex Timing belts are also available with woven polyamide on the teeth and/or the back of the belt.

We can manufacture any length between 1.5 and 22.5 metres.

Different grades of PU are available for special requirements, such as the food industry.

Various steel Cords options: standard, high strength, high flexibility or stainless steel.

Properties and Applications

Gates SUPER Flex™ belts are ideal for conveying and driving applications in a wide range of industries:

- Ceramic and glass industry

- Packaging industry

- Intralogistics sector

- Furniture, paper and wood industry

- Textile industry

- Machine tools ...

Not

Widths

Lengths

Belt materials

Cords

H / T5 / T10 / T20 / AT5 / AT10 / AT20 / ATL10 / ATL20/ HTD®5 / HTD®L5 / HTD®8 / HTD®14

From 10 mm to 170 mm

From min. 1,500 mm to 22,500 mm

PU 92 Shore A (standard), other materials available on request

Steel (standard), high strength, high flexibility, stainless steel

Textile coverings

Coatings

Cleats

Customised finishes

Polyamide on teeth - NT

Over 30 different coatings available

Over 3,000 welded cleat shapes available, special cleats on request

Grinding, milling, drilling and many other finishes available on request

POLAR version for extreme cold

For applications down to -30°C (standard polyurethane can be used from 70°C to -5°C)

With polyamide fabric on the teeth.

VOLT version (Antistatic)

- Statically conductive (ISO 9563) for use under the conditions described in Directive 2014/34/EU-ATEX.

- Nylon fabric option on tooth side

- Antistatic backing material options