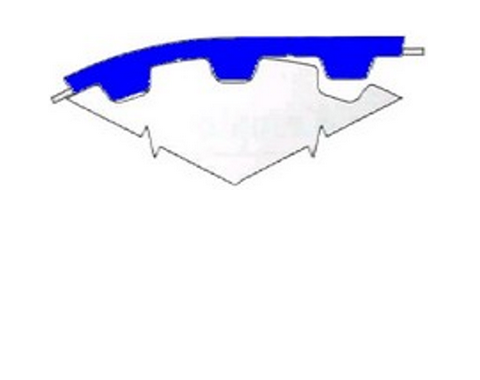

Timing belts with imperial pitches (in inches) :

The first Timing belts had tooth forms based on inch pitches (MXL, XL, L , H, XH, XXH).

These were the first tooth shapes used for power transmission. Most of these belts are made of rubber.

These teeth are very trapezoidal, have few radii and are not very high.

Their old shape has not really been optimised.

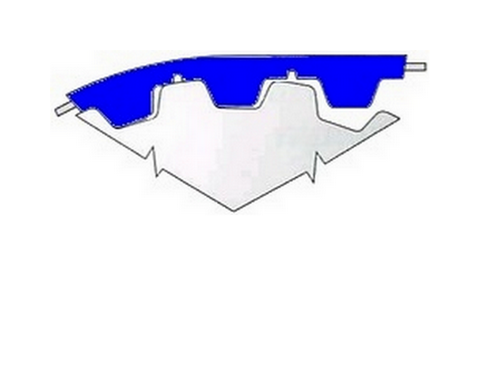

Metric V-belts (in mm) :

T pitch :

Metric belts T2.5, T5, T10, T20 appeared later. Their shape is similar to the imperial pitch belts. They are generally a little higher, and their profile is a little more powerful.

These Timing belts are generally available in rubber for power transmission, and in polyurethane for load carrying, lifting or positioning.

AT pitch :

AT pitches (AT3, AT5, AT10, AT20) have wider teeth, which are more resistant to load. These pitches also have the advantage of being better suited to transporting loads, as the wider teeth provide a larger sliding surface to reduce abrasion.

Slightly stiffer, they run on larger pulleys and are less fatigue-resistant than T-pitch belts.

Timing belts are available in general and in polyurethane for load carrying, lifting or positioning.

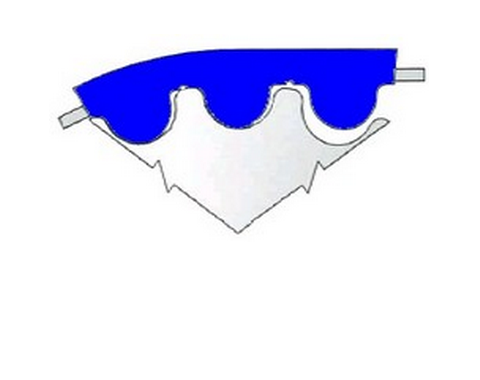

HTD rounded Timing belts :

HTD profiles (HTD5M, HTD8M, HTD14M) have circular teeth. These tooth shapes were developed for power transmission. They are taller than trapezoidal teeth, fit better in the Pulley, allow higher rotation speeds and limit tooth jumps.

This tooth profile is unsuitable for carrying loads and should be reserved for power transmission.

Timing belts are generally available in rubber for power transmission, and in polyurethane for lifting or positioning.

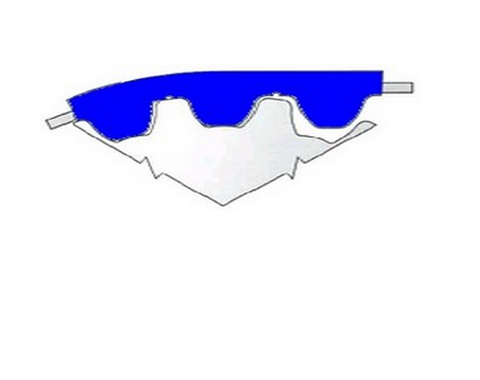

Curved Timing belts STD (STD2M, STD3M, STD5M, STD8M, STD14M), GT (2MGT, 3MGT, 5MGT, 8MGT, 14MGT):

The more recent STD and GT belts were designed by different manufacturers. The aim was to optimise the HTD tooth form for transmission applications. The profile has been redesigned to fit ideally into the pulley teeth, increasing rotation speeds and belt performance.

This tooth profile is unsuitable for load carrying and should be reserved for power transmission.

Timing belts are generally available in rubber for power transmission, and in polyurethane for lifting or positioning.

RPP parabolic Timing belts (RPP5, RPP8, RPP14) :

RPP Timing belts have been designed for driving applications.

This profile is unsuitable for load carrying and should be reserved for power transmission.

These belts are generally available in rubber for power transmission.