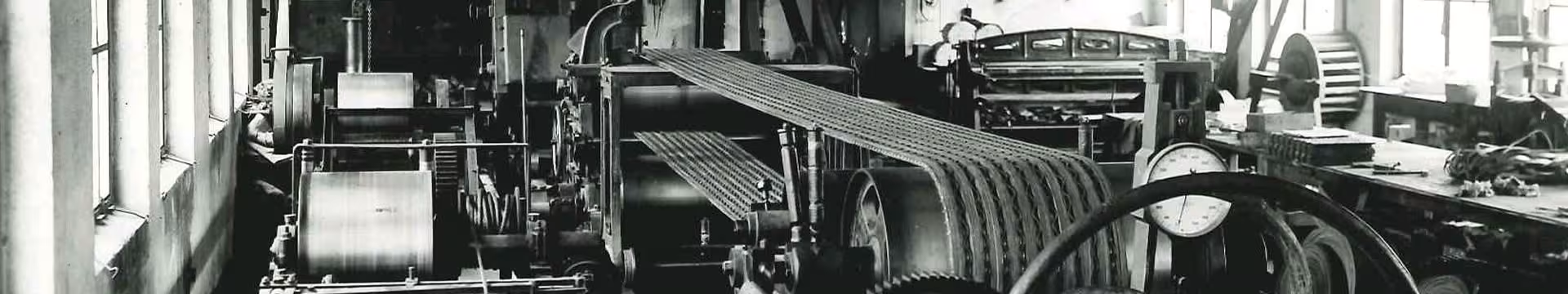

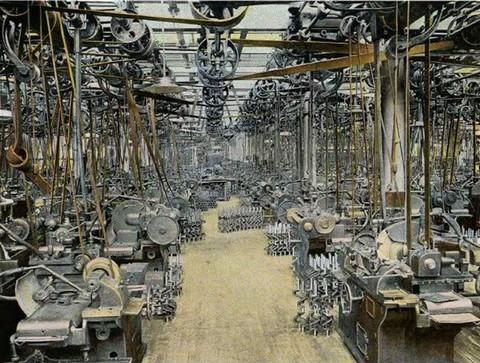

The ubiquitous Belt in factories

In the middle of the 20th century, in factories, a central shaft driven by a motor was used to transmit motion to several machines (milling machines, lathes, drills, etc.) using flat belts.

To transmit more power, it was possible to increase the diameter of the pulleys and widen them to use wider belts. The disadvantage is the space required.

This is why V-belts later replaced them for transmission in shorter lengths. On the other hand, V-belts are not as energy-efficient as flat power transmission belts and timing belts.

Leather, hemp, then polyamide

The materials used for driving belts have evolved over the years. In the past, flat belts were generally made of leather, but by the mid-19th century, cotton, hemp, linen and even wire ropes were also being used.

But power transmission using leather belts remained a popular solution for centuries. Even in the early 20th century, leather belts were the best solution for efficient power transmission. Today, most driving belts consist of elastomer covers combined with a synthetic polymer belt body. Since its introduction in 1938, polyamide has been used mainly as a tensile member in flat driving belts.

A wide range of applications

Power transmission belts have found many new and important uses today. Although V-belts and notched V-belts have somewhat "stolen the limelight", they continue to play a major role in the design of modern machines, particularly at high speeds. They are less visible than in the past, as in many cases they are protected by the machine's chassis and covers and perform their task "out of sight" for obvious safety reasons.

Flat belts can be used on punching machines, presses and other "heavy" machines, transmitting very high loads and absorbing shocks. They protect other parts of the machine (motors, bearings, couplings, etc.) by absorbing shocks as they stretch or slide over the Pulleys.

The following examples illustrate the current use of flat driving belts in various industries:

Postal industry

In mail sorting machines, power driving belts drive the letter transport belts and are essential for achieving precise and particularly fast sorting while reducing energy consumption. At this speed (100,000 letters per hour), the reliability of every part of the machine is essential.

Textile industry

In the textile industry, driving belts and spindle straps are used in the manufacture and processing of yarns and on spinning machines.

Belt performance is crucial to the quality of the finished product, machine reliability and machine energy consumption.

Handling

In parcel sorting and distribution centres, the driving belts drive the conveyor rollers. The belts drive the rollers tangentially so as to transmit the movement to several rollers at the same time and ensure that the parcels are properly conveyed.