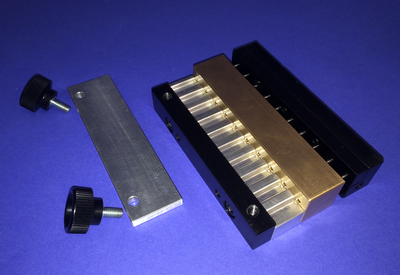

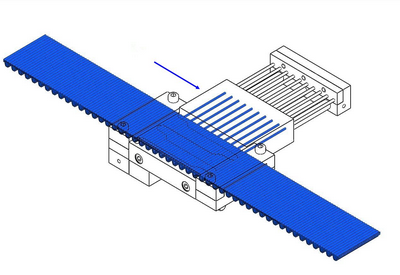

Basic version

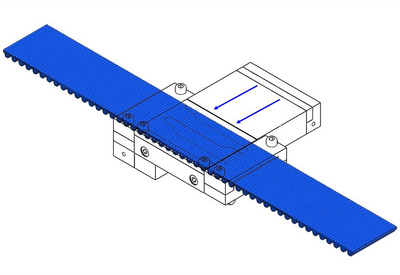

Version with power-on system

Tension system only

(for ERO Joint® HP)

Attaching the Belt

Belt tension

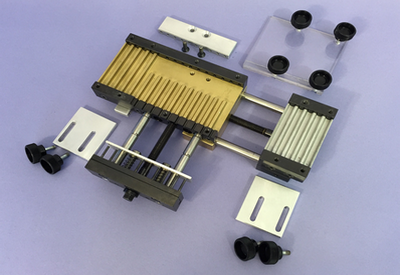

Threading the rods

Poly Chain® GT Carbon™ ERO Joint® assembly video with tooling :

For example:

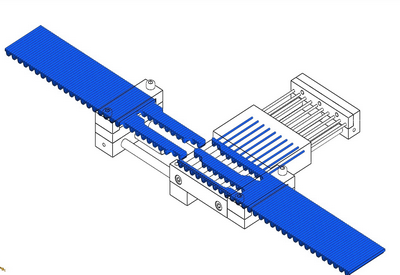

Method of assembling a Poly Chain® GT Carbon™ ERO Joint® Belt with threaded rods.

Step 1

Insert the Belt into the machine. Use the supplied guide to help you.

Stage 2

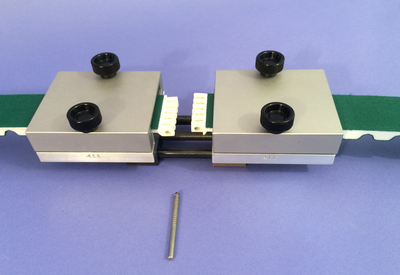

Place both ends of the Belt in the jaws.

Step 3

Tighten the tensioning screw.

Step 4

Fit the screws and lock the tool with the central plate. Next, screw in the loading bars so that the rods fit correctly into the Belt.

Step 5

Check that the pins do not extend beyond the ends of the Belt.