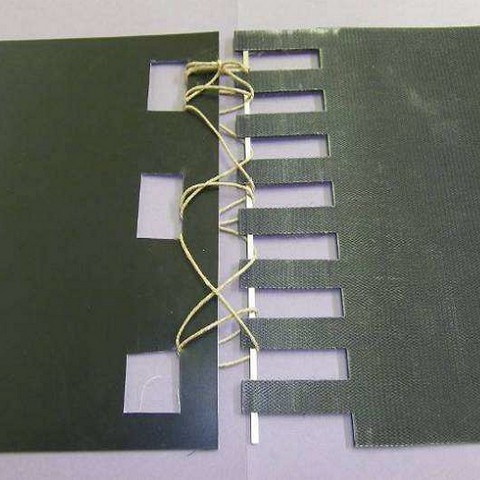

Stage 1

For the belt to pass through, the previous belt can be cut, prepared and assembled at the ERO junction (one side mounted with a single rod or pieces of rod) so as to pull the new belt into the conveyor. (If necessary, secure the assembly by taping the teeth at the edge).

The rod should be removed (cut if necessary) as soon as the belt has passed.

Important note: Observe the direction of travel indicated.

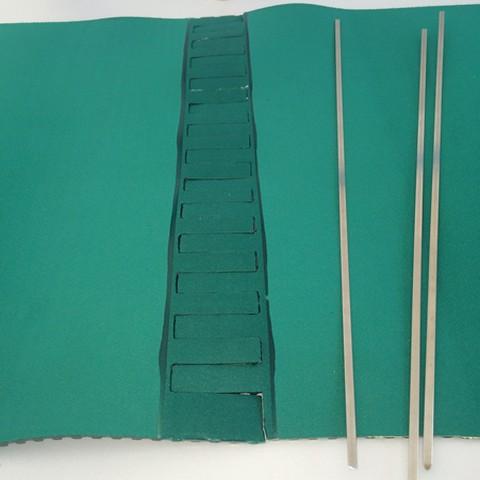

Stage 2

To begin fitting, put a little solution in the hole in each finger of the band.

(The lubricant makes assembly easier).

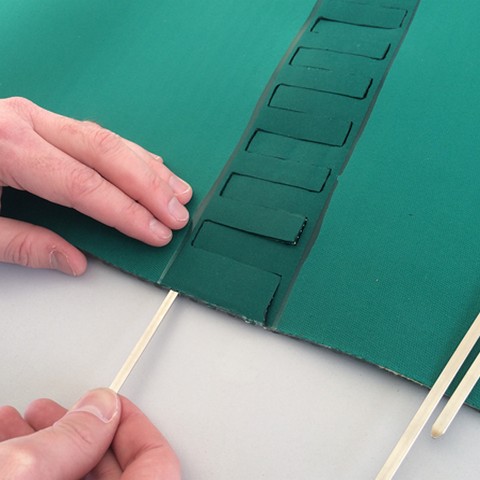

Step 3

Then press the joint fingers of the two ends together quickly so that the lubricant doesn't have time to dry.

Step 4

Finally, push in the pins, making sure they fit through the holes and not under the band on the outside of the fingers.

(We recommend using a board on the band to hold it in place and vice-grips to push in the rod).

(If threading one of the pins proves too difficult, it can be cut off and threaded through the other side of the band or the middle of the band. This can also avoid dismantling the edges if there are any).

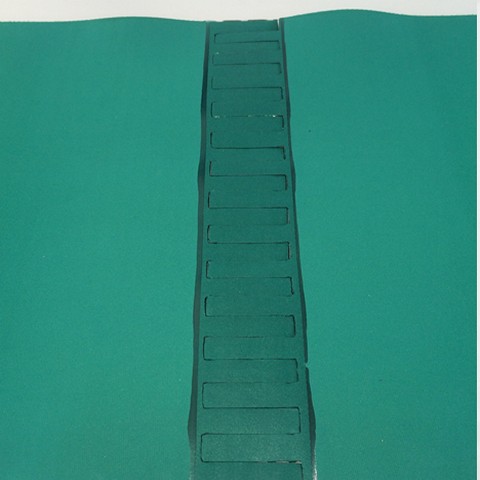

Step 5

It is important to ensure that the rods do not protrude to prevent them from catching. You should also make sure that the rods are well inserted into all the teeth.

Clean up any excess lubricant.

This lubricant is non-hazardous and non-toxic and complies with FDA standards.

The belt can be tensioned (like a fused belt), adjusted and the conveyor started up.

The solution is a lubricant that will solidify and Glued over time. As well as making assembly much easier, it prevents any slow migration of rods out of the running belt.