Please select the appropriate minimum Pulley diameter according to the different PU/Polyester grades The best qualified materials for Pulleys are steel, high alloy steel, aluminium or polyamide when plastics are used. Please bear in mind the low coefficient of friction μ when using plastics.

Pulleys recommended for V-belts

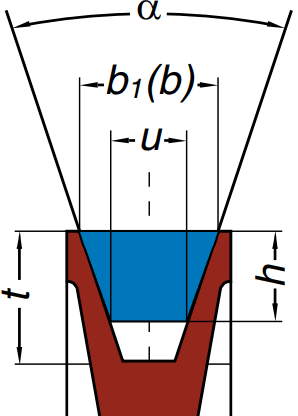

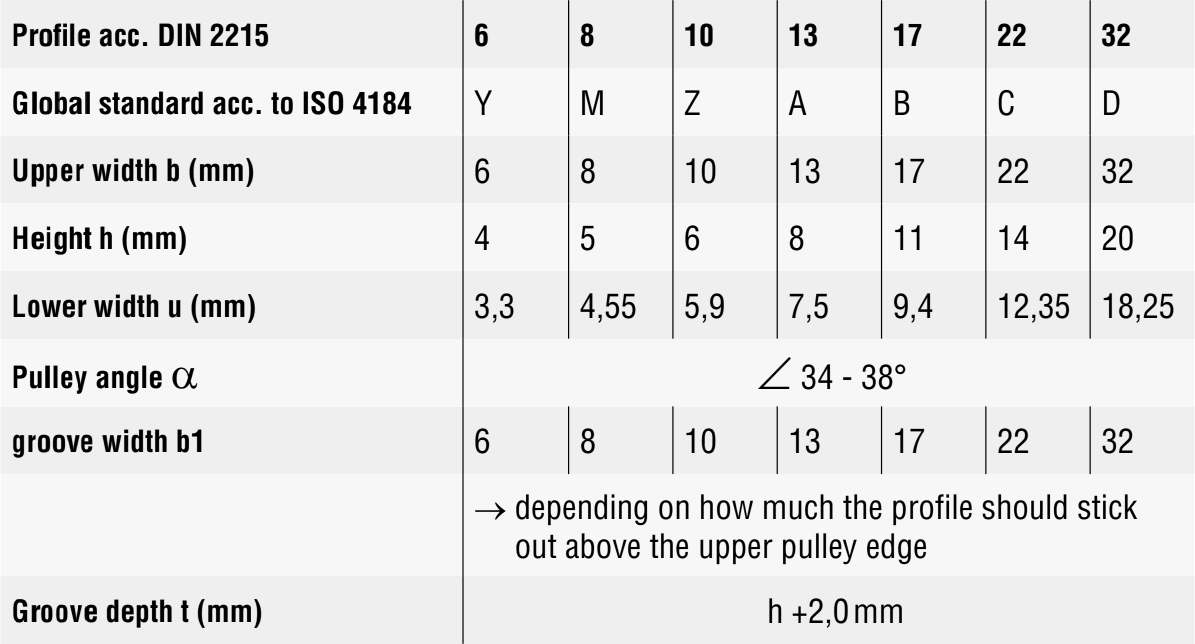

Pulley design for Belt profiles

When it comes to matching belts and pulleys, it is generally recommended to work with materials and/or surfaces that create sufficient friction with the PU/TPE, for example aluminium or steel. This is important to ensure good power transmission. Caution: aluminium can cause discolouration (blackening) of the belts. All other Pulleys, guide elements or sliding beds should be made of materials with a low coefficient of friction, e.g. PE or HDPE.

Pulleys for round belts

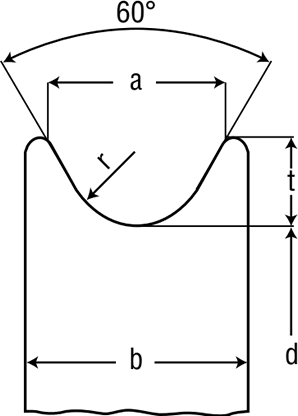

To simplify conveyor design, these are often the same pulleys used for V-belts. However, V-belt pulleys are not ideal because the grooves provided can literally squeeze a round belt and cause premature damage. We therefore recommend using a special round Belt Pulley. Unlike a V-belt, round belts must be in contact with the sides and bottom of the groove, which must be taken into account when manufacturing the respective pulleys.

Pulleys for T-profiles

The power transmission of these belts takes place on the flat area of the back of the belt. This means that the V-guide is not a power transmission element, but only has a guiding function.

As a result, the drive guide must be free in the groove with little clearance and must never be tightened!

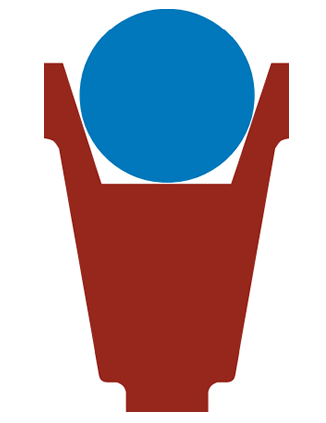

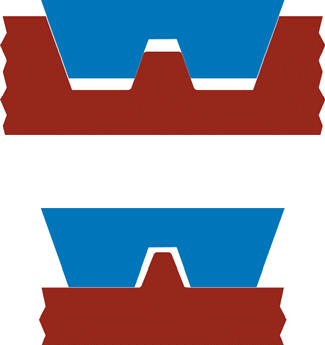

Pulleys for twin V-belts

In the case of parallel V-belts, a distinction is made between use as a drive belt or as a spreader belt.

In the case of a drive, the design of the Pulleys must be such that the power is transmitted through the flanks.

In spreading table applications, it has proved wise to guide the belt exclusively via the central groove and to drive it via the underside of the profile.