Pretensioning force (N)

Table value x width of belt used (mm)

Shaft load (N)

Value taken from table x actual width of belt used (mm) / number of axles (shafts)

Maximum transport weight (kg)

Table value x width of belt used (mm) x 0.05

For Belt models not listed, check the k1% value on the corresponding data sheet and use the general formula at the bottom of the page to determine the required parameters.

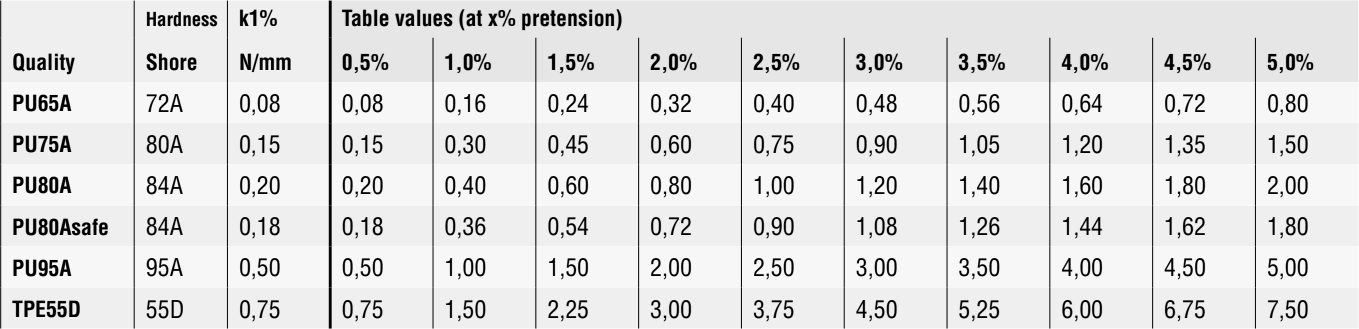

Belt thickness (in mm): 1.0

Belt thickness (in mm): 1.2

Belt thickness (in mm) : 1.6

Belt thickness (in mm) : 1.8

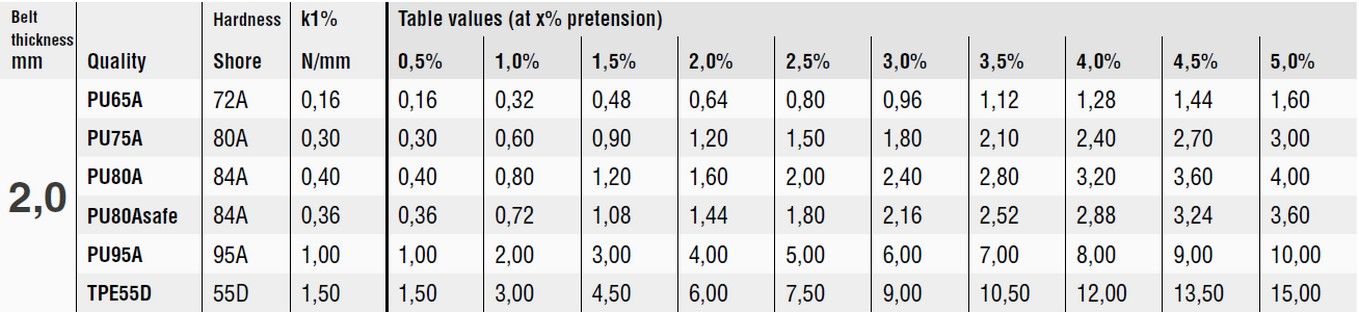

Belt thickness (in mm) : 2.0

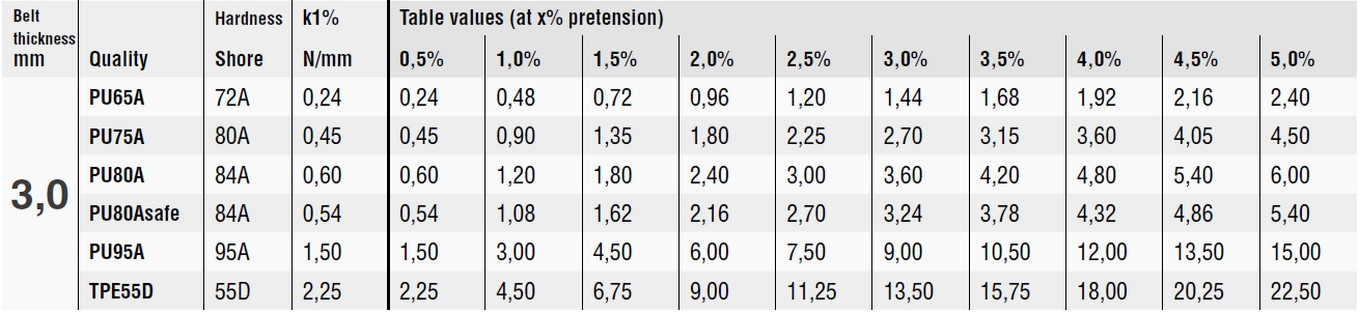

Belt thickness (in mm) : 3.0

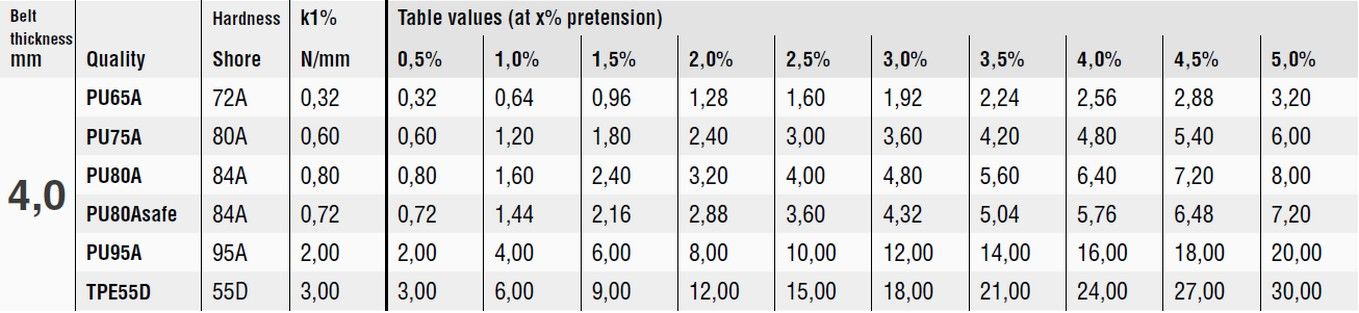

Belt thickness (in mm) : 4.0

General calculation formulae for Belt design

Pre-tension force (N)

k1% (N/mm) x belt width (mm) x pretension (%) x 2

Axle load (N)

k1% (N/mm) x belt width (mm) x pre-tension (%) x 2 / number of axles

Max. transport weight (kg)

k1% (N/mm) x belt width (mm) x pre-tension (%) x 0.1