Discover our troubleshooting solutions for ERO joint® HP Timing belts and ERO joint® WT wide timing belts.

Troubleshooting guide for ERO joint® HP Timing belts

Problem encountered

Possible reason for fault

How can we solve the problem?

Rupture of the junction

Too much voltage

Incident or wear

The rod has been inserted incorrectly / The teeth of the joint are not aligned correctly / dismantling of the belt

We advise you to reduce the voltage

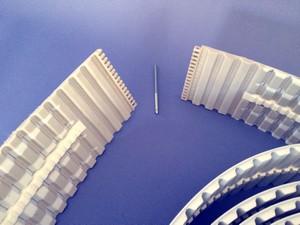

The photo below shows a case where the rod has not been correctly inserted (you can see that the Cords in the junction are not damaged). The possible reason for the junction breaking could be due to the junction teeth being misaligned.

Please read the assembly instructions carefully and observe the following instructions:

Do not dismantle the Belt (please consult us if necessary)!

The stem is difficult to insert

You have no lubricant

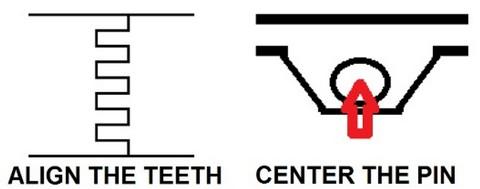

Teeth are misaligned at the junction

You have not used a chamfered shank

Use water to aid insertion

It is imperative that the teeth are perfectly aligned at the junction

You need to insert a chamfered stem (don't hesitate to ask us for one)

Troubleshooting guide for ERO joint® WT wide Timing belts

Problem encountered

Possible reason for fault

How can we solve the problem?

You notice that the junction is broken, broken off

Too heavy a load

Accident or wear

Too much tension

Modify the current joint with a reinforced 5-rod joint

We advise you to reduce the tension

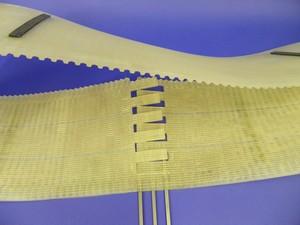

End fingers spread apart

The Belt is fitted upside down, wrong direction of travel

You haven't used the Glued and lubricant that we supplied to you

Check that the Belt is correctly fitted and that it runs in the correct direction.

The pins have moved towards the edges of the Belt

You restarted too quickly after installing the Belt (glue and lubricant did not have time to dry).

There is too much stress in the belt

Replace smooth rods with notched rods